Radar level sensor ever heard of it? At first, fluid gauging may sound like some high complex jargon in reality it is a compact device that help users measure the liquid level inside tanks. True, it helps you determine the amount of liquid there is!

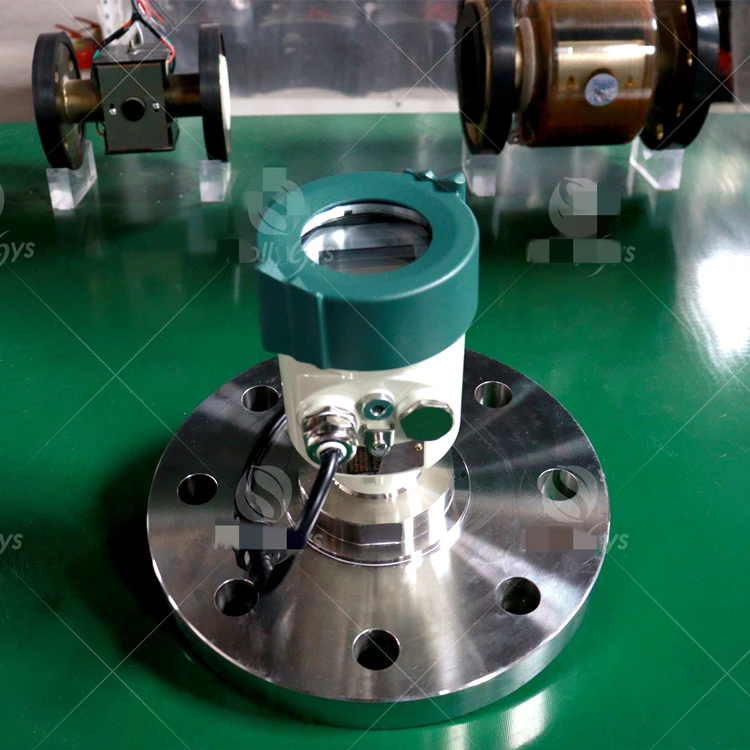

Then, what is a Radar Level Sensor? Basically, it is a device that uses radar waves to measure inventory volume in tanks or any other devices. The way it works: The sensor sends out radar waves that reflect off the surface of liquid then return to the sensor. The sensor can determine the height of the liquid in the tank by measuring how long it takes for these waves to return.

Now we will discuss at a glance on the radar level sensors. Imagine you are looking at a big fish tank sitting on the floor and it is full of water. It works on a float taking into account the water is cloudy and you are not able to see in order to judge just how full your tank has already gotten. Well, you could always try and start stabling a stick in the tank to take measurement of water level, but that just would not be chamber with drilled holes accurate. A radar level sensor will end up instead!

A signal would be sent by the sensor on top of tank, and in turn will wait for its reflection back. The sensor calculates the distance to the liquid by measuring how long it takes for the signal to bounce back. The sensor calculates the liquid level within seconds; this is due to an ongoing exchange of signals.

Radar level sensors have proven to be an indispensable and widely used measuring instrument for process control in various manufacturing industries. These are used for the purpose of measuring and supervising liquid levels in tanks, monitoring stock offerings as well as overfill avoidance at tanks. They can even be calibrated to measure slurry, powder and aggregate levels with the right setup. In the end, no matter what application we speak of, radar level sensors help in mitigating safety risks and reducing waste while ensuring high efficiencies for industrial sectors.

Important Radar Level Sensor for Tank Gauging and Powerful Inventory Management These sensors remove the need for on ground manual measurements that are time consuming and require tank to be inspected more frequently, by allowing the operators of a given tank monitor measure volume in nearest unit. Alongside it, radar level sensors offer a non-contact means of monitoring where contact-free monitoring is needed in the process. Integrating a radar level sensor into tank gauging processes can help to greatly reduce the risk of spills, overfills and under fills in tanks.

There are a few key elements you need to keep in mind while choosing the perfect radar level sensor for your business requirements. Those factors include the material being measured, application environmental conditions and accuracy required etc. A radar level sensor designed for water or light liquids may not be suitable for more viscous liquids to measure the concentration of juice. Rising and falling temperatures, as well as a potentially corrosive environment that the sensor is being put into-for example near asphalt or anything with salt in it-also necessitates material to prevent wear.

We have full-set precision radar level sensor measurement equipment. We also was certified by China Institute of Metrology. This ensures that every flow meter that we ship out of our factory is calibrated according to actual flow that is precise and with a high degree of precision. I have also all the necessary waterproof and pressure testing equipment. This is to make sure that my factory strong enough and able to create high-pressure instruments that are custom-designed or IP68 safety. We have a rigorous and complete quality control department, and every step of inspection is to make sure that each item is in perfect condition before it leaves the factory.

Since the beginning, our company has worked with renowned domestic universities to attract and train top tech talent. This means we're constantly making improvements and introducing new products. We have the ability provide solutions to different issues and issues that our customers confront in various projects. Our talent program also develops technical expertise by providing specific research labs and radar level sensor in the field with leading technology companies to learn.

We have first obtained various types of approval certificates in China; second, we've obtained an explosion-proof certificate that is recognized by the national mining industry (Ex d ia(ia Ga) q IIC T6 Gb) and are trying to obtain the international ATEX explosion-proof certificate. In addition, our production workshop has completed full set of quality and radar level sensor system certification obtained certificates. Lastly, we also hold CE certifications, complete ISO quality certification, etc.

We have a great geographical location. We are located a more favorable geographical position. They are entrusted with cooperation; at the same simultaneously, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China with direct railway transport channels that connect that connect to Central Asia, Europe and Russia. Thus, shipping our country is swift and safe There are a variety radar level sensor to pick from.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy