مستشعر مستوى الرادار سمعت عنه من قبل؟ في البداية، قد يبدو قياس السوائل وكأنه لغة معقدة ومعقدة، لكن في الواقع هو جهاز صغير يساعد المستخدمين على قياس مستوى السائل داخل الخزانات. نعم، فإنه يساعدك على تحديد كمية السائل الموجود!

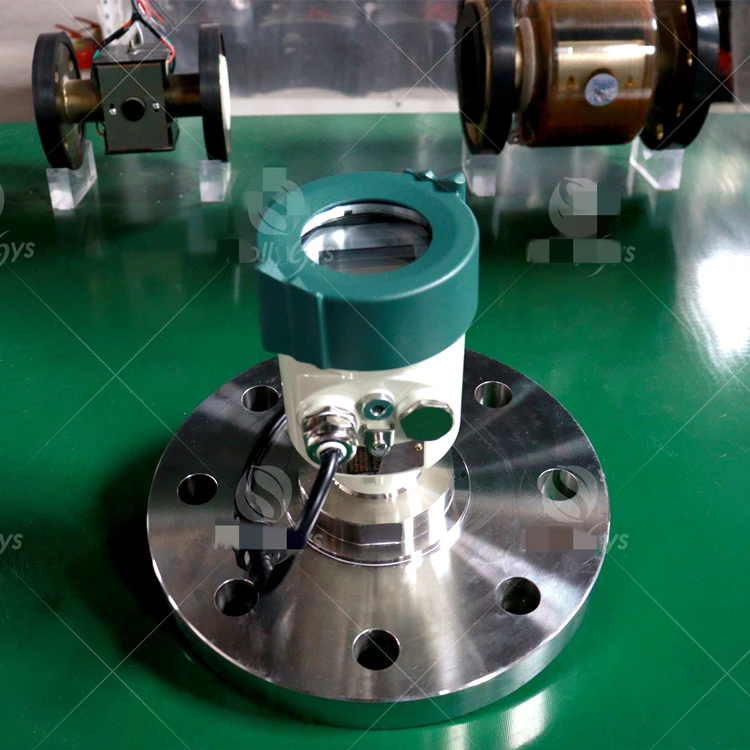

ثم، ما هو جهاز استشعار مستوى الرادار؟ في الأساس، إنه جهاز يستخدم موجات الرادار لقياس حجم المخزون في الخزانات أو أي أجهزة أخرى. طريقة عمله: يرسل المستشعر موجات رادار تنعكس عن سطح السائل ثم تعود إلى المستشعر. يمكن للمستشعر تحديد ارتفاع السائل في الخزان عن طريق قياس الوقت الذي تستغرقه هذه الموجات للعودة.

الآن سنناقش بشكل سريع حول أجهزة استشعار مستوى الرادار. تخيل أنك تنظر إلى خزان سمك كبير موضوع على الأرض ومليء بالماء. يعمل بنظام عوامة مع الأخذ في الاعتبار أن الماء ضبابي ولا يمكنك رؤيته لتحديد مدى امتلاء الخزان. حسنًا، يمكنك دائمًا محاولة إدخال عصا في الخزان لقياس مستوى الماء، لكن ذلك لن يكون دقيقًا كما لو كان هناك ثقوب محفورة. بدلاً من ذلك، سيكون لديك جهاز استشعار مستوى الرادار!

سيقوم المستشعر بإرسال إشارة من أعلى الخزان، وسينتظر انعكاسها العائد. يحسب المستشعر المسافة إلى السائل عن طريق قياس الوقت الذي يستغرقه الإشارة للعودة. يقوم المستشعر بحساب مستوى السائل خلال ثوانٍ؛ وذلك بسبب تبادل مستمر للإشارات.

أثبتت أجهزة استشعار مستوى الرادار أنها أداة قياس لا غنى عنها وتُستخدم على نطاق واسع للتحكم في العمليات في مختلف الصناعات التصنيعية. تُستخدم هذه الأجهزة لقياس ومراقبة مستويات السوائل في الخزانات، مراقبة عروض المخزون وكذلك تجنب الإفراط في ملء الخزانات. يمكن حتى ضبطها لقياس مستويات اللب والمسحوق والمواد المجمعة مع الإعداد المناسب. في النهاية، بغض النظر عن التطبيق الذي نتحدث عنه، فإن أجهزة استشعار مستوى الرادار تساعد في تقليل المخاطر الأمنية وتقليل الهدر بينما تضمن كفاءات عالية للقطاعات الصناعية.

مستشعر مستوى الرادار المهم لقياس خزانات وإدارة المخزون القوية. هذه المستشعرات تزيل الحاجة إلى القياسات اليدوية على الأرض التي تستهلك الوقت وتتطلب فحص الخزان بشكل أكثر تكرارًا، وذلك من خلال السماح للمشغلين بمراقبة قياس الحجم بالوحدة الأقرب. بالإضافة إلى ذلك، تقدم مستشعرات مستوى الرادار وسيلة مراقبة غير ملامسة حيث يكون هناك حاجة لمراقبة بدون تلامس في العملية. دمج مستشعر مستوى الرادار في عمليات قياس الخزانات يمكن أن يساعد في تقليل مخاطر التسرب والملء الزائد أو النقصان في الخزانات.

هناك عدد قليل من العناصر الرئيسية التي تحتاج إلى أخذها في الاعتبار أثناء اختيار مستشعر مستوى الرادار المثالي الذي يلبي متطلبات عملك. تشمل هذه العوامل المادة المراد قياسها، وظروف البيئة التطبيقية، والدقة المطلوبة وما إلى ذلك. قد لا يكون مستشعر مستوى الرادار المصمم للماء أو السوائل الخفيفة مناسبًا للسوائل الأكثر لزوجة لقياس تركيز العصير. ارتفاع وانخفاض درجات الحرارة، وكذلك البيئة المحتملة للتآكل التي يتم وضع المستشعر فيها - على سبيل المثال بالقرب من الإسفلت أو أي شيء يحتوي على ملح - يتطلب أيضًا استخدام مواد لمنع التآكل.

لدينا مجموعة كاملة من معدات قياس مستشعرات مستوى الرادار الدقيقة. كما حصلنا على شهادة من المعهد الصيني للمعايرة. ويضمن ذلك أن كل عداد تدفق نشغّله من مصنعنا يكون معايراً وفقاً للتدفق الفعلي بدقة عالية جداً. ولدي أيضاً جميع معدات اختبار مقاومة الماء والضغط الضرورية. وذلك لضمان متانة المصنع وقدرته على إنتاج أدوات تعمل تحت ضغط عالٍ ومصممة حسب الطلب أو ذات تصنيف أمان IP68. لدينا قسم رقابة جودة دقيق وشامل، ويتم في كل مرحلة تفتيش دقيق للتأكد من أن كل قطعة تكون في حالة مثالية قبل مغادرتها المصنع.

منذ البداية، تعاونت شركتنا مع جامعات محلية مرموقة لجذب وتدريب الكفاءات التقنية المتميزة. وهذا يعني أننا نقوم باستمرار بإجراء تحسينات وإطلاق منتجات جديدة. ولدينا القدرة على تقديم حلول لمختلف القضايا والمشاكل التي يواجهها عملاؤنا في مشاريع مختلفة. كما يُطور برنامج الكفاءات لدينا الخبرة التقنية من خلال توفير مختبرات بحث متخصصة وأجهزة استشعار رادارية للمستوى الميداني بالتعاون مع شركات تقنية رائدة للتعلم.

أولاً، حصلنا على مختلف أنواع شهادات الموافقة في الصين؛ ثانياً، حصلنا على شهادة مقاومة الانفجار المعترف بها من قبل قطاع التعدين الوطني (Ex d ia(ia Ga) q IIC T6 Gb)، ونعمل حالياً على الحصول على الشهادة الدولية ATEX لمكافحة الانفجار. بالإضافة إلى ذلك، أكمل ورشة الإنتاج الخاصة بنا نظام الشهادات الكامل لنظام الجودة وأجهزة الاستشعار الرادارية للقياس، وحصلنا على الشهادات اللازمة. وأخيراً، نمتلك أيضاً شهادات CE، وشهادة الجودة ISO الكاملة، وغيرها.

لدينا موقع جغرافي ممتاز. نحن نقع في موقع جغرافي أكثر تفضيلاً. تم إسناد التعاون إليهم؛ وفي الوقت نفسه، تقع مدينة تشنغتشو على بعد 50 كيلومترًا منا وهي أكبر مركز سككي في الصين، وتضم قنوات نقل بالسكك الحديدية المباشرة التي تربط بآسيا الوسطى وأوروبا وروسيا. وبالتالي، فإن شحن البضائع إلى بلدنا سريع وآمن. هناك مجموعة كبيرة من أجهزة استشعار مستوى الرادار يمكن الاختيار من بينها.

حقوق النشر © شركة كايفنغ كامبودا للآلات الصناعية المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية