The world’s biggest thermal flow meters are made to measure how much gas is flowing in factories around the world. Instead, they do so by measuring how gas flows through a pipe when it is heated. This technology is invaluable as it helps companies understand how much gas they are using – and to check that everything is working efficiently.

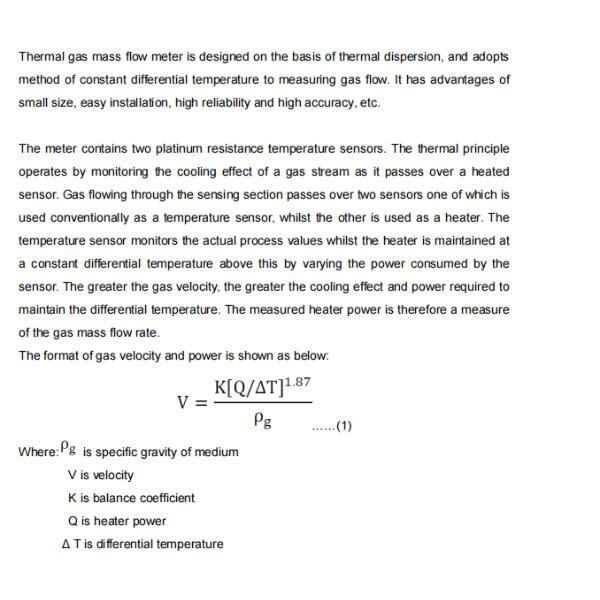

Thermal flow meters are great at determining how fast gas is moving. The meters are equipped with a sensor that heats the gas as it flows through the meter. The sensor then calculates how fast the gas cools. This is the manner in which we know how fast the gas is flowing. We will use this for determining gas flow rate.

Thermal flow meters rely upon the concept of heat transfer. When gas comes through the meter, it steals some warmth from a sensor. The sensor tracks how quickly the gas cools, which is a way for us to determine how fast it is moving. This is to help us monitor how much gas is being used.

Heat transfer is significant for heat flow meters. All gases are not transformed by heat in the same way. Knowing the thermal conductivity of a gas, we are able to accurately measure the flow direction. This enables companies to track their gas consumption.

There are countless good reasons to utilize thermal flow meters in manufacturing facilities. They are incredibly accurate when it comes to measuring gas flow, which is helpful for companies to know how much gas they’re using. They’re also simple to install and maintain. And because thermal flow meters are trusty, and provide essential information to keep all the moving parts in motion.

We have first received various types certifications of approval in China and, secondly we have received the explosion-proof certification recognized by domestic coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb), and are in the process of thermal flow meter principle for an international ATEX certificate for explosion-proofing; in addition our manufacturing workshop has completed complete set of environmental and quality system certifications and have obtained certifications; lastly we also hold CE certificates; full ISO quality certification, etc.

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is thermal flow meter principle to ensure that every product is flawless when leaves the factory.

Our location is fantastic. We are thermal flow meter principle a more favorable geographical area. Zhengzhou City is 50 km away and the largest railway hub China. It has direct rail transport routes that connect to Central Asia, Europe, and Russia. Shipping from us is secure and speedy, with plenty of possibilities choose from.

Over the years, our company worked with well-known thermal flow meter principle in the United States in order to train and recruit best technical talent. This assures us that we are constantly improving and adding new products. We have the ability to provide solutions for different problems and issues that our clients confront various projects. The talent plan we have developed also helps to develop professional technical talents by providing dedicated research labs and cooperating in the industry with advanced technology firms to gain knowledge.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy