Did you know that how a scientist or engineer can be so specific in identifying the volume of liquid moving through a pipe? It's a fascinating question! There are flow meter sensors that can provide the answer. Flow Meter Sensor: Flow meter sensor is a device that can measure how fast the liquid flowing on it in pipeline or tubes. Many jobs depend on this measure. Such as in food manufacturing, water purification and the oil & gas sector. Most of these processes would be hard to control without flow meter sensors.

Quantifying the amount of liquid flowing is critical in most industries. In short, it allows a peaceful life. In addition, when the reading is accurate on flow, it can be used by workers to easily find problems in advance and prevent expensive breaks in work from occurring. The vital is the flow meter sensors, which provide real-time insight into how quickly fluids are traveling from a place to another. This has the property that any firm can immediately observe when liquids are beginning to flow and take steps accordingly. This way business can change the flow of their liquids, they have a record to keep their products safe and at high quality which will lead them improve production overall.

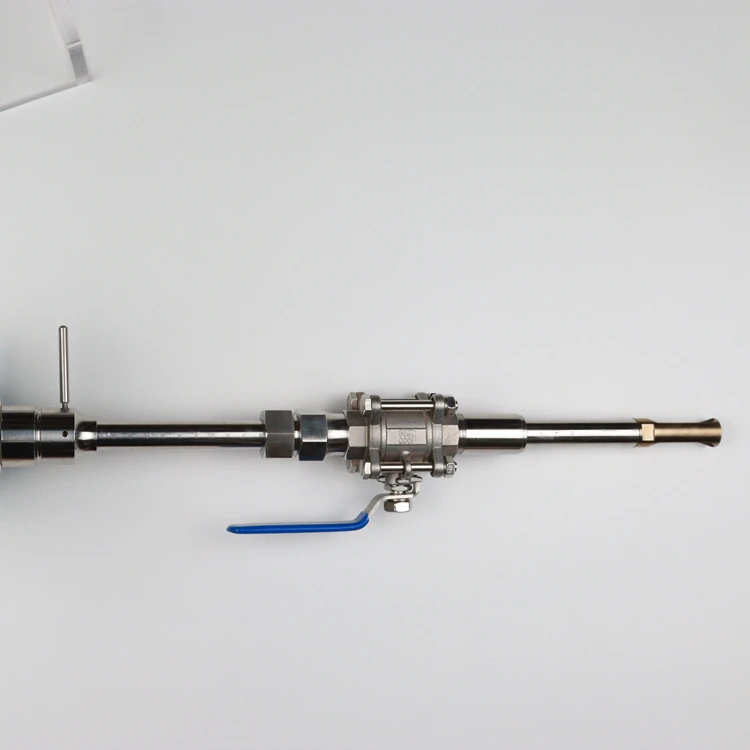

The specific jobs require flow meters of different types, which are the basic sensors. So for instance, a magnetic flow meter is great at measuring liquids (think water) that are electrically conductive. A mass flow meter, on the other hand is great for measuring gases like air. While choosing a flow meter sensor, some of the very vital factors to keep in mind are here. Consider the liquid in question, the nominal diameter of its pipe, fluid flow rate along with temperature and pressure depending on conditions. When selecting the appropriate flow meter sensor becomes difficult, an expert in this field should always be consulted or a flow meter selection guide can make things easier. This can help you make sure that the right sensor is exactly what you need.

This is the same for all tools and devices including flow meter sensors. Make sure they are coded in correctly and checked weekly to see if they working. But you also need to keep them clean on a regular basis. The sensors must be checked periodically to ensure they are measuring correctly. If problems do surface such as dust on the sensor or air bubbles in the liquid, these are often things can be resolved by examining and cleaning it carefully. Routine inspections discover issues before they become disastrous and is cost-effective. Proper maintenance of the flow meter sensors will save a business from unnecessary downtime and keep its operations running smoothly.

Even though a great number of flow meter sensors functioned with simple mechanical parts, new technology developments significantly improved the state of things. For instance, ultrasonic flow meters make use of sound waves to measure liquid flows with some fantastic accuracy. In contrast, the Coriolis meters exploit a phenomenon to detect liquid flowrates. Today, flow meters are easy-to-install and comes with advanced smart components to provide of real-time data, maintenance assistance and remote connectivity. This enables the workers to keep track of the sensors far away from them without having to stand right next to it. Flow meter sensors may even be configured to function in adverse conditions, like very hot or high-pressure atmospheres. These characteristics have many industrial applications

We have first received various types certifications of approval in China and, secondly we have received the explosion-proof certification recognized by domestic coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb), and are in the process of flow meter sensor for an international ATEX certificate for explosion-proofing; in addition our manufacturing workshop has completed complete set of environmental and quality system certifications and have obtained certifications; lastly we also hold CE certificates; full ISO quality certification, etc.

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is flow meter sensor to ensure that every product is flawless when leaves the factory.

We are situated in a premium geographical location. Within 60 kilometers, there Zhengzhou International Logistics Port, the largest air-based logistics port in Central China, with abundant logistic and air options; there are many international flow meter sensor companies such as FEDEX, UPS, DHL, TNT, etc. Zhengzhou City is 50 km away, is biggest railway hub in China. It has direct railroad transportation routes that connect that connect to Central Asia, Europe, and Russia. Thus, shipping from us is fast and secure and there are plenty of routes to pick from.

Over the years, our company worked with well-known flow meter sensor in the United States in order to train and recruit best technical talent. This assures us that we are constantly improving and adding new products. We have the ability to provide solutions for different problems and issues that our clients confront various projects. The talent plan we have developed also helps to develop professional technical talents by providing dedicated research labs and cooperating in the industry with advanced technology firms to gain knowledge.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy