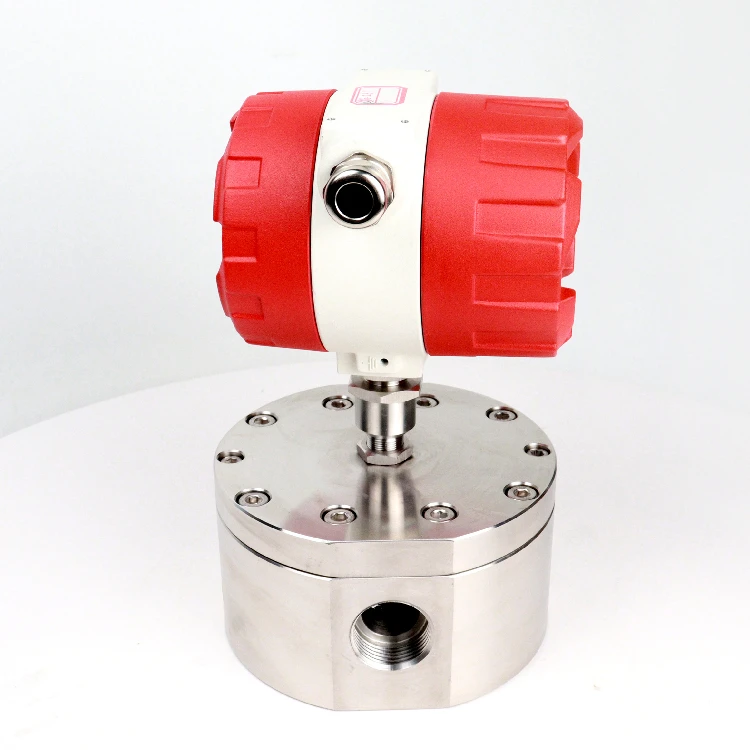

We are excited to add a new layer as air flow meter sensor are small but effective, and really provide an essential measurement for many things. They can measure pressure in gases, liquids, and many other things. These sensors function by converting mechanical force, such as pressure or strain, into electrical signals. Put differently, when you press on the sensor, it alters the way current flows through it. This variation in electricity can be quantified, and we can convert it into data that gives us insights into what is going on.

The mostly silicone-based material these sensors are created from. Silicone has unique properties that assist in it's very accurate pressure detection ability. The sensor consists of small grooves or lines which deform when the user applies pressure. As these grooves get compressed or distorted, the silicone alters its electrical resistance. This also alters how electricity flows through the silicone. That change in resistance is wire-transmitted to a computer on which pressure reading analysis can easily be plotted and interpreted.

IntroductionPiezoresistive pressure sensors operate in various places such as factories, laboratories, and even in home. They are very important devices that help in controlling the pressure in different machines and systems. As an illustration, in hydraulic applications, these sensors contribute to maintaining constant liquid pressure, which is crucial to prevent machine damage. Too high or too low pressure can cause equipment failure.

Piezoresistive sensors have a lot of simple applications in the food industry. They also help monitor the pressure in machines that process food, including slicers and brewing machines. The machines operate correctly and the food gets processed safely. We typically encounter these sensors in the hospitals/medical setups to read the blood pressure of the patients. This is important information for doctors, as it can help them diagnose and treat a variety of health conditions.

There are many significant reasons behind the preference for air flow meter over the other types of pressure sensors. Ví dụ: They are very accurate (in high values)First use case. This allows them to sense even the smallest differences in pressure, an aspect that is relevant to all sorts of applications. You’ll also find them quite robust as well. They are resistant to extreme temperatures, and harmful chemicals and corrosive materials and do not degrade in changeable conditions

Piezoresistive pressure sensors are widely used in the automotive and aerospace sectors. These sensors are used in cars for many essential functions. They measure tire pressure, airbag pressure, and brake pressure. This improves safety during handling and when getting on and off the vehicle. Low pressure on, for example, tires can change how the car behaves on the road. These sensors also sense the fuel pressure and engine oil pressure. It is essential information to ensure the engine works properly and retains its efficiency over a long time.

These are very important in aerospace industry piezoresistive sensors. They are employed in rocket engines, satellites, and other spacecraft to measure the pressure of various liquids and gases. During a rocket launch, for example, it is important to understand how much precise amount of pressure is being stored in the empty fuel tanks. These sensors ensure that anything functions in the right way. Piezoresistive sensors measure the air pressure rushing over the wings and body of airplanes. Clinical data provides pilots with important information on the aircraft speed, altitude and heading, which is necessary for flight safety.

Since the beginning, our company has worked with renowned domestic universities to attract and train top tech talent. This means we're constantly making improvements and introducing new products. We have the ability provide solutions to different issues and issues that our customers confront in various projects. Our talent program also develops technical expertise by providing specific research labs and piezoresistive pressure sensors in the field with leading technology companies to learn.

Our location is fantastic. We are piezoresistive pressure sensors a more favorable geographical area. Zhengzhou City is 50 km away and the largest railway hub China. It has direct rail transport routes that connect to Central Asia, Europe, and Russia. Shipping from us is secure and speedy, with plenty of possibilities choose from.

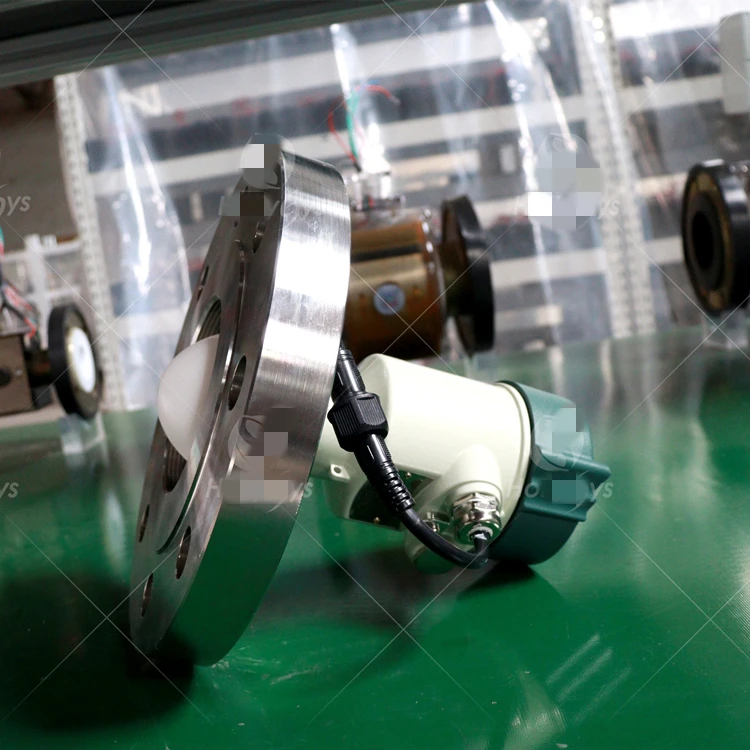

We have a complete range of high-quality measuring calibration equipment and have obtained certification from the China Institute of Metrology, to ensure that every flowmeter that we ship out of the factory has been calibrated using real flow and is accurate and true precision. I also have complete waterproof and pressure testing equipment. This is to be sure that facility has the strength and capability to build high-pressure instruments, or IP68-protection. We have a stringent and complete quality control department, and every step of the inspection process is made sure that each product is flawless after leaving the piezoresistive pressure sensors.

We have first received various types certifications of approval in China and, secondly we have received the explosion-proof certification recognized by domestic coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb), and are in the process of piezoresistive pressure sensors for an international ATEX certificate for explosion-proofing; in addition our manufacturing workshop has completed complete set of environmental and quality system certifications and have obtained certifications; lastly we also hold CE certificates; full ISO quality certification, etc.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy