Selecting the Ideal Flow Meter For Your Demands

Oil and gas flow measurements use a variety of different devices to determine the quantity or rate at which liquids (or gases) are being produced. These devices are crucial by nature of several tasks that rely on knowing how quickly a substance is passing through the pipe. However, the problem is that there are so many flow measurement options available such as Paddlewheel Flow Meters, Magmeters and Ultrasonic level sensors. Which one do you choose for your specific requirement? To delve deeper into the realm of flow measurement devices, let us help you in scouting suitable options - full steam ahead to FMDs.

Three basic types of flowmeter can be distinguished: (1) those that measure the velocity; (2) mass, immunity to temperature and pressure changes in gas density or viscosity- independent tables about fluid behavior than volume counts.

Some of them are the most used in flow measuring devices.

Orifice plates are placed in the pipe to slow down fluid movement and measure its velocity.

Venturi: These devices measure flow in a way similar to Orifice plates but start with least restriction possible.

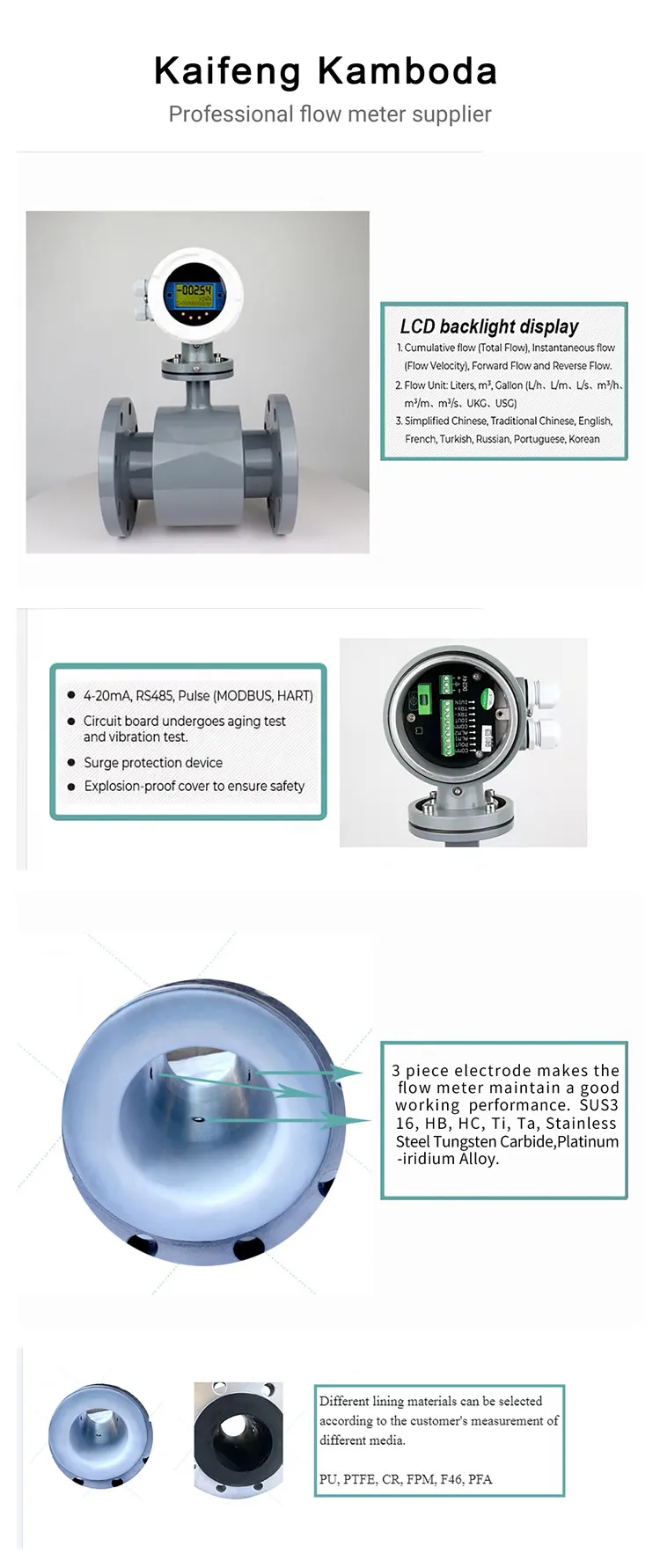

Magnetic flowmeters. These are, as the name implies a magnetic field to track fluid movement. Voltage induced due to the fluid which is conductive passes through the magnetic field gives an idea of how much flow rate.

Ultrasonic flowmeters: These devices measure the liquid's speed of flow by looking at how fast ultrasound waves travel through it.

There are other flow measuring devices such as turbine, positive displacement and Coriolis flowmeters which cater to unique purposes in various industries.

The Flow Measurement DeviceAdapted To Your Needs Selection of the device suited to your needs depends on many factors. These differences can include the type of fluid being measured, a range in flow rates is required (high and low), how viscous the fluid will be & what accuracy level you need to obtain. Some hardware might be better suited for certain industries or uses cases.

In industries such as food and beverage, hygienic flow measurement devices are used which keeps the product clean for measuring. In contrast, industries such as oil and gas may need devices that can live in higher temperatures or pressures.

Flow Measurement Technology Innovations and Trends

Flow measurement technology is an ever-evolving field with constant advancements and trends that define the industry. Newertech advancements has recently introduced some wireless flow measurement devices can send data to a control system without any more physical connections.

Additionally, the durability of flow measuring system (with advanced materials like ceramics and composites) have increased with reduced maintenance. A new trend is also the provision of diagnostic capabilities built into these devices, which enables early detection in case something goes wrong.

Flow Measurement Devices - Troubleshooting and Maintenance

Like any mechanical equipment, flow measurement instruments need routine maintenance and sometimes troubleshooting to maintain themselves in the best conditioned. Pipe blockages, or a calibration issue with your furnace can be other common problems as well.

You may need to clean, check or possibly even test your flow measurement device for accuracy.

If something goes wrong, the quicker we can identify a problem, the faster downtime is prevented. If the loss of blood mushrooms is particularly bad in your home, proper identification and treatment may require professional help.

Here are some interesting information in terms of best practices for accurate and trustworthing reading from your measurement device.

Chronically calibrate for complete accuracy

Invest in the RenewCrew | Scheduled maintenance and cleaning to avoid debris build-up

Monitor regularly to recognize potential pitfalls early

Choosing the most appropriate flow meter according to Desired fluid, flow rate range and other application related aspect

These best practices will help you get the most out of your flow measurement device, minimize risk for operational disruptions and ensure reliable results over time.

To sum things up, flow measurement devices are important for any type of industry or purpose. Getting to know the various types of devices, making smart choices for your application and caring for them properly will help you achieve accurate measurements over time.

We have first obtained various forms approval certificates in flow measurement devices and, secondly we have gotten an explosion-proof certificate that is recognized by the local mining industry (Ex d ia(ia Ga) q IIC T6 Gb) and we are trying to obtain the international ATEX explosion-proof certification; in addition production workshop in our factory has completed complete set of quality and environmental system certifications and has obtained certificates; finally we also have CE certifications; complete ISO quality certification, etc.

We have full-set precision calibration measurement equipment. In addition, we have obtained certification from China Institute of Metrology. This ensures that each flow meter we send from the factory is calibrated to actual flow that is precise and with a high degree of precision. I also have complete pressure and tension testing equipment and waterproof testing equipment to ensure our factory is able to withstand the rigors of and capability to design IP68 or high-pressure protection instruments. We have a strict and complete quality control flow measurement devices. Every step of inspection process is to ensure that every product is flawless before it leaves the factory.

We are in a prime geographical position. We a superior geographic area. They are entrusted with cooperation; at the same at same time, Zhengzhou City, 50 kilometers away from us, is the largest rail hub in China, with direct railway transport routes to Central Asia, Europe and Russia. Shipping from us is quick and secure there are plenty of flow measurement devices to choose from.

Since many years we have worked with some of the most prestigious universities in the nation attract and train the best technical talent. This means that we're flow measurement devices improving and adding new products. We can find solutions for different problems and issues that our clients have to deal with different projects. However, our talent plan involves fostering technical talent, offering specific research labs cooperating with top technology companies within the industry to develop.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy