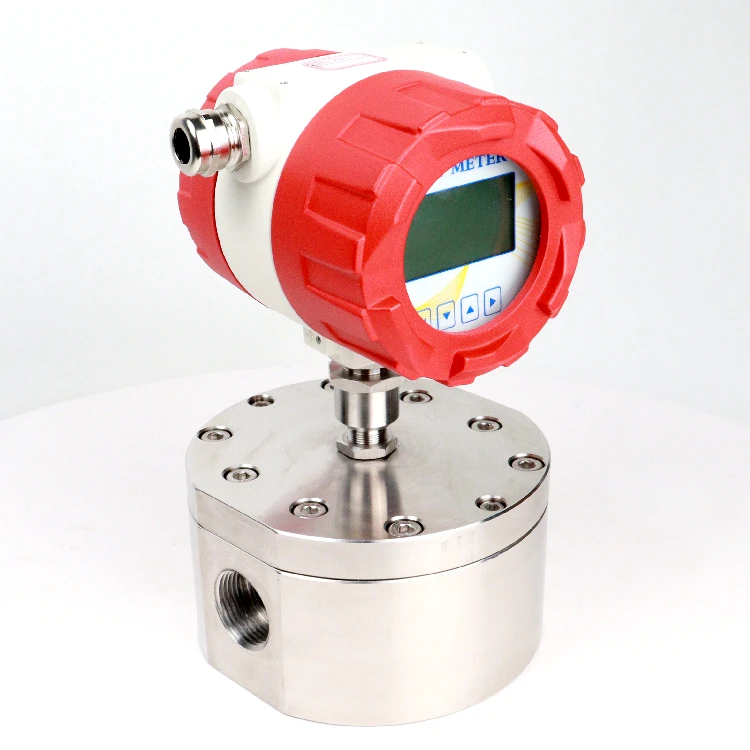

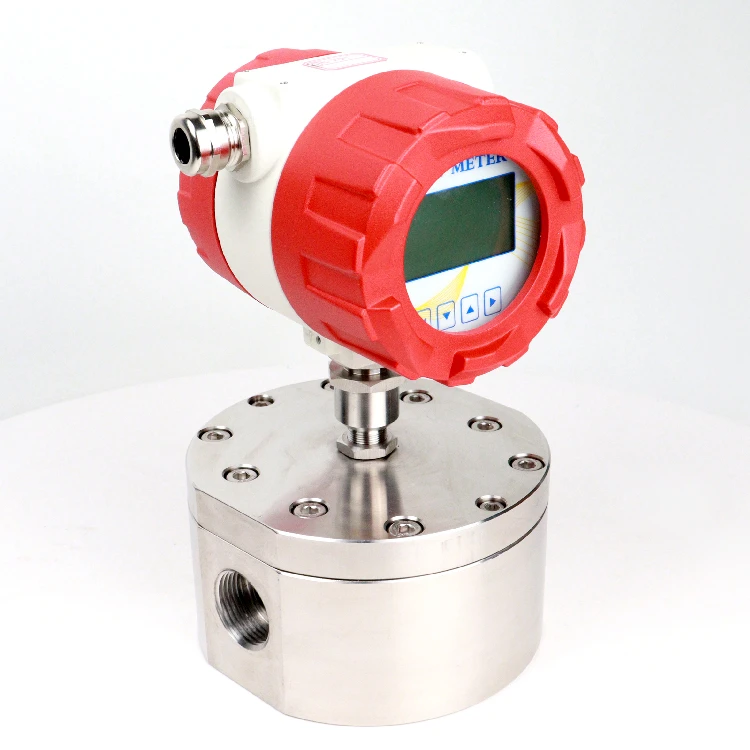

Ever heard of a gear meter? The devices are small but still pack a pretty big punch when it comes to measuring how fluids flow in tubes and mechanical equipment. Think of it as a tiny gland that supervises the flow of liquid. Inside that case are two clever rotating gears and, as fluid whirls past them they fun to rotate at higher-and-higher speeds. The gun also drove a gear flow meter, which counted rotations of the gears to determine how much fluid had passed through the system. So that, it measures the method of flow!

The nice thing about gear flowmeters is that, even on lower-viscosity fluids they provide a very accurate reading. This will help make sure the numbers they report regarding how much fluid has flowed are pretty close to what actually went past them. Why is this important? So, proper measurements allow to concatenate the required volume of a substance for use in factories and other industrial operations. When a factory uses too much liquid, it can lead to problems. Therefore, in such case a dependable and durable tool like gear flow meter is important to have everything running on track.

One of the benefits of gear flow meters is that they are useful to monitor and observe how fluids move. Such a device could measure how much fluid is was currently flowing. They are able to note any changes in the flow rate and can alert staff if something seems off. It might be that a leak along the system is allowing much more flow to pass or, it could happen just for an example. As a result, the gear flow meter would sense this change and inform to the workers at once. This avoids fluid wastage and assures that all activities in the factory are running perfectly.

Gear flow meters additionally provides data, constant and on the location. For instance, the fact that measurements are in real-time means that workers can see what is going on at any time as well. It is critical as it enables shop floor workers to take instant decisions which can directly impact the working of a factory. This includes the ability for workers to see in real-time, when their process suddenly drops off flow, allowing them time-to-act and prevent any damage from occurring within the equipment or lost production due to downtime. This prompt response ensures everything in the factory runs effectively and smoothly.

Because workers will have access to actual data in real time, they can react right away should any changes occur. It is a must have feature in fast running factory. If the machine is not receiving fluid at optimum levels, it may reduce throughput or even cause damage. This means workers must be able to instantly view and react, in real time due to the importance of their decision making keeping things on schedule.

The flow meters that are treated as the best to measure in factories, is a gear flow meter. They are small in size, simple to configure and provide highly accurate measurements quite rapidly. It affords them usability in a number of industries including chemicals, as well as food and drinks processing to medicine or oil and gas. Gear flow meters can serve the latter quite well, as they are based on a physical principle that makes them ideal for each sector individually.

In this sense, a continuous named type analysis and the development of new types are performed by flow meters. So you spend on getting authenticated gear flow meters that work even better in every setting industrial environment to get overall performance benefits from it as well. They are a crucial component for maintaining factory innovation and efficiency. Open more to buy some gear flow meters because the better they will be and of course, which means that however good this assumption.

We have first obtained various types of approval certificates in China; second, we've obtained an explosion-proof certificate that is recognized by the national mining industry (Ex d ia(ia Ga) q IIC T6 Gb) and are trying to obtain the international ATEX explosion-proof certificate. In addition, our production workshop has completed full set of quality and gear flow meter system certification obtained certificates. Lastly, we also hold CE certifications, complete ISO quality certification, etc.

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is gear flow meter to ensure that every product is flawless when leaves the factory.

Our location is excellent. We have a superior geographic location. Zhengzhou City 50 km away and is also the largest rail hub in gear flow meter. It has direct railway transportation routes that connect Central Asia, Europe, and Russia. Shipping from us is secure and speedy, with plenty of options choose from.

Our company has been cooperating renowned universities in the country for several years, has been able to recruit and training top technical talent. This will not only guarantee our ongoing technological advancement, but also continuously improves and introduces new products. We can find solutions to various problems and issues that our customers encounter in their various projects. The talent plan we have developed also helps to develop professionals with gear flow meter skills by providing specific research labs for and collaborating within the industry with top technology company's study.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy