Measurement of flow is an important process in which the quantity fluid or gas moving through pipe line or channel should be determined. Well say controlling is like knowing how many water gallons come out of the faucet or how many ml are being poured into a glass.

In industries like oil, gas, chemicals and water treatment flow measurement is key. It is essential to ensure that the substance in required quantity passes through pipelines. In addition to this, high-quality products are used in transport as well and have a measurement of all accurateness.

Items of Concern When Measuring the Flow

To measure flow, there are several things to consider. The main influential factors on the readings are: pipeline diameter, viscosity of transported substance and temperature. Also the type of flow meter is very important. These can also be used to measure the flow, such as an ultrasonic or magnetic flowmeter and a differential pressure type flowmeter.

Recent years have brought forth a slew of innovative technologies for more accurate flow measurement. This type of meter is the Coriolis flow sensor, which is widely used in both chemical and food processing plants because it measures not only volume but also mass flow to be less affected by changes in material density. Clamp-on ultrasonic flow meters are suitable for liquid and compensate measuring, so they do not have to touch the subject. The advantage has been revealed in water treatment plants, where it is able to measure flow rates of the liquid inside a pipe without interfering with flow.

True flow measurement goes far beyond the numbers and can result in savings and financial efficiency. In oil and gas sector, a minor error in measurements can amount to massive losses. Industries like refineries can minimize losses and improve overall performance if they ensure the most accurate flow measurements. In addition, the rides must comply with strict standards and serve only high-quality products that require accurate measuring. In particular, in the food industry ingredient measurements have to be accurate every time to ensure the final products are as good and taste as they should.

Flow Measurement is important but accurate measurement can be difficult to achieve because of a lot of elements. Problems like temperature or pressure fluctuating, substance viscosity change and the existence of air bubbles/impurity could also impact on measurement result. Using a Coriolis flow meter to track mass flows is one way that industries can measure something other than volume even with changes in viscosity among others. Another important aspect needed for the accuracy of flow meters is regular maintenance and calibration.

To sum it up, flow measurement process is mandatory in most of the industries today. This is mainly about cost savings and increasing efficiency in the plant, but also relates to product quality during transportation for materials used. Incoming product flow measurement can be challenging, but the application of new technologies and good maintenance practices helps to achieve consistently accurate results.

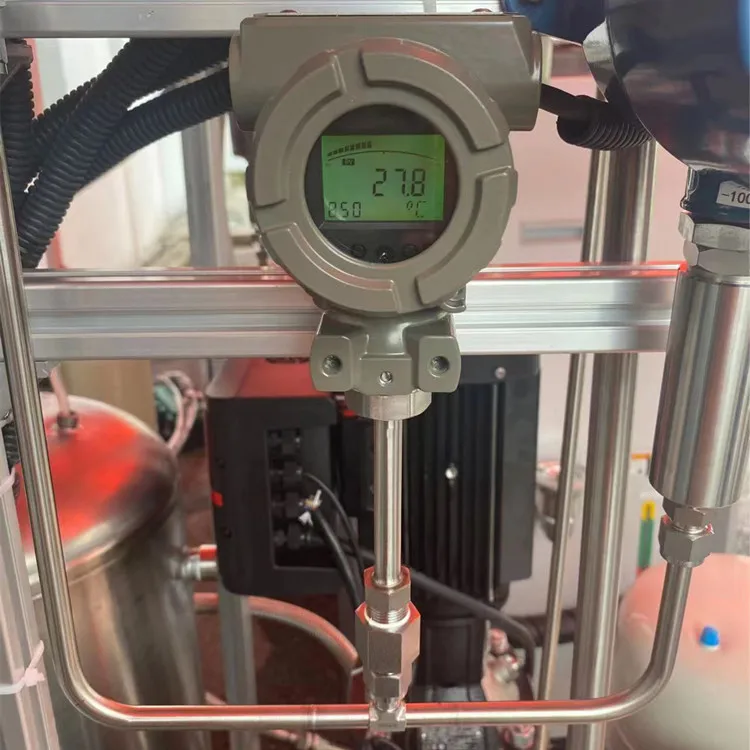

We have a complete set of precise measurement calibration equipment and have obtained certification from the China Institute of Metrology, which ensures that every flowmeter we send out of our factory is calibrated using real flow and has precise and precise. I also have all the necessary waterproof and pressure testing equipment. This is to be sure that the factory I run is equipped with capacity and strength to build high-pressure instruments, or IP68 safety. We have a strict and thorough quality inspection department, and every step of the inspection flow measurement is to ensure every product is flawless once it has left the factory.

We have received various certifications China. Second, we have obtained the certificate of explosion proof recognized by the coal mining industry in China (Ex d IA (ia Ga) q T6 Gb) We are also trying to obtain the international ATEX certificate. Furthermore, our manufacturing flow measurement has passed the necessary certifications and certificates our quality system, environmental system, and have obtained CE certifications.

Our company has been cooperating renowned universities in the country for several years, has been able to recruit and training top technical talent. This will not only guarantee our ongoing technological advancement, but also continuously improves and introduces new products. We can find solutions to various problems and issues that our customers encounter in their various projects. The talent plan we have developed also helps to develop professionals with flow measurement skills by providing specific research labs for and collaborating within the industry with top technology company's study.

Our location is excellent. Within 60 kilometers, there Zhengzhou International Logistics Port, the largest air-based logistics port in Central China, with abundant options for logistics and air; there are a variety of international express companies such as FEDEX, UPS, DHL, TNT, etc. assigned to cooperate. At the same the same time, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China that has direct railway flow measurement channels that connect that connect to Central Asia, Europe and Russia. Therefore, shipping from our country is swift and secure, and there are many routes pick from.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy