They are considered special tools for measuring the flow of liquid or gas through a pipe. These meters are critical for dozens of different jobs in which devices can help ensure the appropriate amount of material is used in different processes. In this lesson, we'll look at how DP flow meters operate, how they help with measurement, the advantages and disadvantages of using this type of device, the different versions of it, and some common repair issues you may come across.

How do DP flow meters work? DP flow meters employ the principle of so-called “differential pressure”. `` They measure the pressure difference between two points in a pipe, in which liquid or gas is flowing. So, if we know this pressure difference, we can find out what the flow is precisely. DP flowmeters are comprised of two elements; a sensor for measuring the pressure differential and a transmitter for converting the information to a flow rate.

Perhaps the greatest advantages of DP flow meters are that they provide very precise measurements. Since they depend on the difference in pressure, they are not influenced by variations in temperature, or thickness of the liquid or gas, which may create problems in other flow meters. This is what makes DP flow meters a perfect solution for a wide variety of applications where accurate readings are key.

There is a lot of good that can come out when a DP flow meter is used in industrial tasks. For instance, they can help businesses save money by more effectively using materials and wasting less. They could likewise improve products by ensuring that the proper amount of material is used for each process. On top of that, DP flow meters can also address equipment problems by verifying the flow rate and detecting potential problems before they can lead to trouble.

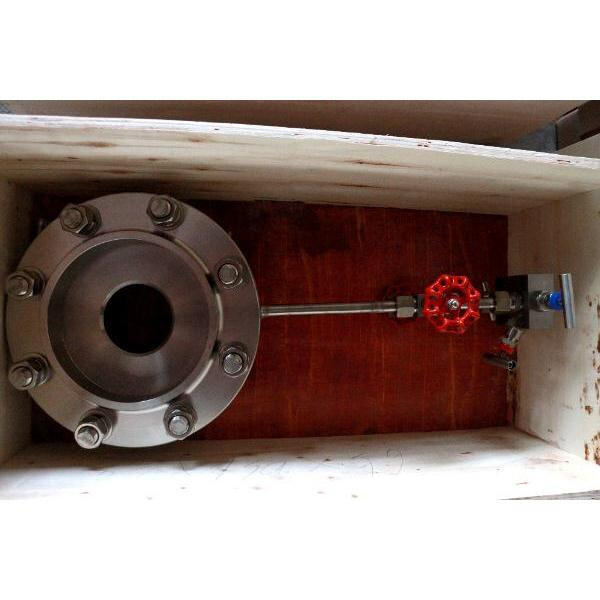

Several types of DP flow meter design options exist, and each has its good and bad attributes. Some examples include orifice plates, venturis, and flow nozzles. The least expensive and simplest is the orifice plate, but it can impose a significant pressure drop. Venturi tubes are more precise and accurate and have smaller pressure loss, but, of course, cost more. Flow nozzles work similarly to venturi tubes but function best under high-pressure conditions.

Although DP flow meters are generally dependable, there are times when they do not provide accurate readings. Sensor fouling, signal interferences, or calibration problems are some typical problems. To overcome these issues, one should periodically inspect and service the mitochondria, check for any obstructions in the pipe, and to calibrate the instrument as necessary. By troubleshooting their DP flow meters in this way, businesses can ensure that they still provide accurate readings.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy