Clamp-on flow installations should consist of the dedicated DP flow transmitters used for quantifying how much liquid, or gas is passing in a pipe. These types of tools are important in many industries because they need to measure the flow of how things work. They function with the help of DP which is an abbreviation used for Differential Pressure. This means that they binary check between two points at a pipe based on the cadence of pressure. One way to measure this difference is using certain differences that are observed editing the speed of a liquid or gas when flowing within the pipe. This is extremely valuable information to ensure the systems are actually behaving as expected.

So, what to consider when choosing a DP type flow transmitter? One of the most important things you need to know is what type of gas or liquid are being measured It is the liquid or gas for which we need to determine multiple properties. Since various liquids and gases behave uniquely, this selection choice becomes a very critical one during selecting fluids in real instances. The next thing you have to think about is: how large the pipe? The size of the pipe can have an influence on how well the transmitter will work because a bigger one may need more or different equipment than a smaller. Finally (and this one is important) consider the margin of error that you can tolerate.

Job Type: Some jobs need very accurate measurements while others do not. Different forms of a KAMBODA dp flow meter serve different applications and therefore you should be clear on the purpose before zeroing your down to one technology or form. A little research can go a long way otherwise you would not know which one to settle for.

A DP flow transmitter is put into service by following a set of steps to ensure its proper functioning. To begin, ensure the pipe is free from moisture and any contaminants. When there is the presence of dirt or moisture, it affects how that transmitter works. You will then secure the transmitter to the pipe and can run it back to a control system or data logger capable of reading in from your transmitters. Did You Calibrate The Zero Point of the Transmitter? Then, modify it to meet the dynamics of that liquid/gas stream. To accomplish this, you will use a specialized tool such as the KAMBODA flow transmitter or pressure gauge to assess the readings and ensure everything is precise.

At times, the DP flow transmitters too encounter difficulties that influence their exactitude levels. A clogged and/or dirty sensor is a common problem. The readings can be wrong if the sensor is not clean and that will lead to significant trouble. Electrical interference is also one of the major problems were some other electrical signal mess with our Transmitter Output. This could also result in misreading. Cleaning the sensor properly or moving wires away from interference might be necessary to correct these issues. And this is where knowing how to troubleshoot these problems comes into play so your transmitter does not fail altogether.

The flowmeters based on differential pressure are one of the preferred methods for measuring the flow. With these, you make sure that the data is correct since they are considered as highly accurate. They can also be used in a great many environment which makes them very functional. These sensors are most useful in various industries that require measuring of liquid and gas quantities inside pipes with different diameters. Yet, they do also have their limitations. They might not work well in very small pipes as an example or when your temperature are too high. KAMBODA turbine flow transmitter have to be verified and calibrated every so often for accuracy as well. In short - to get the most out of them, you must know when to use them and also how not.

Our location is excellent. Within 60 kilometers, there Zhengzhou International Logistics Port, the largest air-based logistics port in Central China, with abundant options for logistics and air; there are a variety of international express companies such as FEDEX, UPS, DHL, TNT, etc. assigned to cooperate. At the same the same time, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China that has direct railway Dp flow transmitter channels that connect that connect to Central Asia, Europe and Russia. Therefore, shipping from our country is swift and secure, and there are many routes pick from.

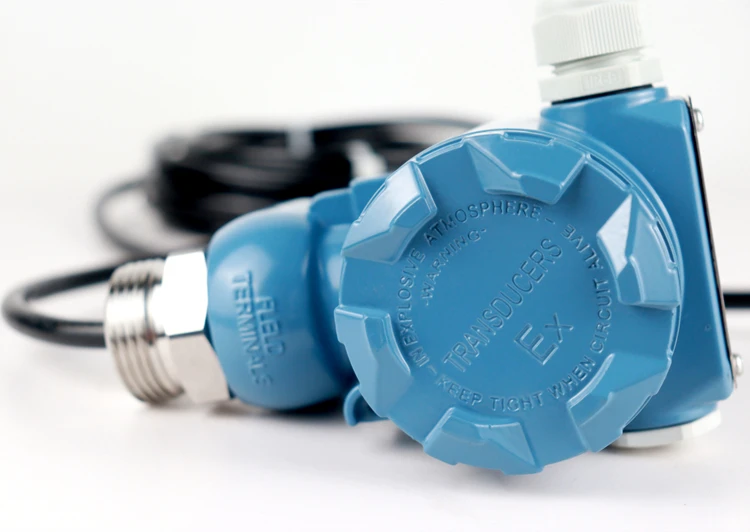

We have first received various types certifications of approval in China and, secondly we have received the explosion-proof certification recognized by domestic coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb), and are in the process of Dp flow transmitter for an international ATEX certificate for explosion-proofing; in addition our manufacturing workshop has completed complete set of environmental and quality system certifications and have obtained certifications; lastly we also hold CE certificates; full ISO quality certification, etc.

We have a complete set of precise measurement calibration equipment and have obtained certification from the China Institute of Metrology, which ensures that every flowmeter we send out of our factory is calibrated using real flow and has precise and precise. I also have all the necessary waterproof and pressure testing equipment. This is to be sure that the factory I run is equipped with capacity and strength to build high-pressure instruments, or IP68 safety. We have a strict and thorough quality inspection department, and every step of the inspection Dp flow transmitter is to ensure every product is flawless once it has left the factory.

Our company has been collaborating with well-known domestic universities several years and has been able to recruit and educating top technical experts, which will only guarantee our ongoing technological advancement as well as continuously improving and introduces new products. We are able to come up with solutions to different issues and issues our customers face in different projects. At the same time our talent program is also fostering professional technical Dp flow transmitter by providing dedicated research laboratories and cooperating with advanced technology companies in the industry to learn.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy