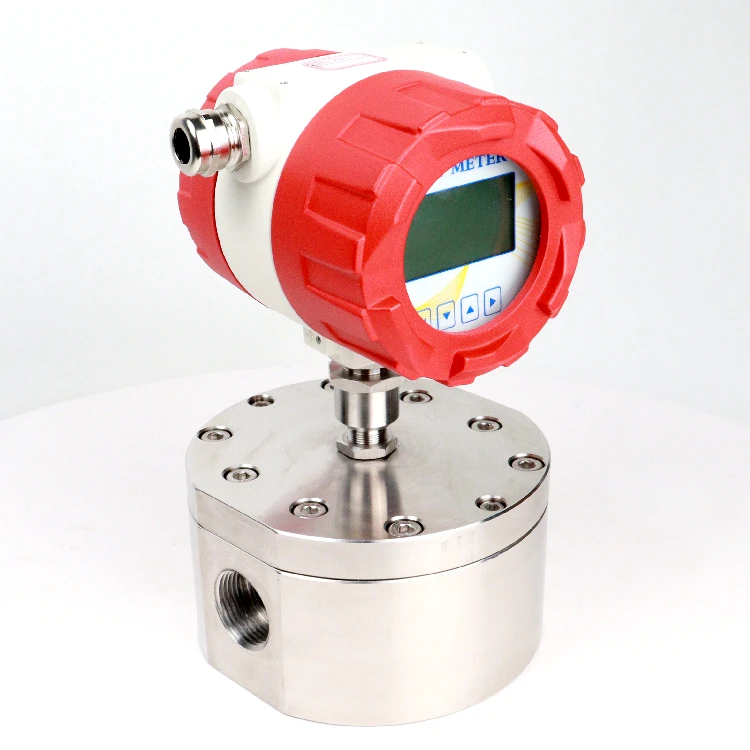

Analog Flow Meters: Analog flow meters are specific to measuring how much liquid or gas passes through pipes. Inside these meters are some key components that work together to provide us with the readings. Flow sensors; instruments that transmit flow data, and chemical interfaces appear useful here since they remind us of fans. Nowadays, the market offers a wide range of analog flow meters that are suitable for different applications due to their numerous advantages.

Analog: Typically analog flow meters are less expensive to maintain Because they usually do not need so much upkeep as digital flow meters, which could be a monetary financial saving over the years. Plus, they are quite a bit more rugged than digital flow meters so if the area you work in is rough you can count on these types of models to not only survive but also provide stable and accurate measurements!

Flow Together AN Analog flow meters are so versatile they can be used in just about every industry. For example, they can be used to measure the volume of water that flows through a municipal clean drinking-water plant where water is cleaned and distributed for people to use. They are also commonly employed in the oil and gas industry to meter fuel flow, used for measuring how much natural gas is moved from well-heads. You will also see these meters often used in other industries like chemical manufacturing, pharmaceuticals and even the food and beverage industry to help ensure that products are made safely (using correct concentrations) and efficiently.

This demonstrates the importance of accuracy! Analog flow meters may exhibit a range of accuracy, which will determine how accurate the readings must be and this is highly dependent on your particular application or industry. For example, in pharmaceutical and chemical industries the measurements are to be very precise because even a minor mistake can result into huge losses. Conversely, the industry related to food products and drinks does not demand accuracy matching the first sector so its needs can be a bit more forgiving.

Due to the continuous moving parts, regular calibration is required for analog flow meters. After finish this setup process, it must be calibrated to test and adjust the meter so that it provides correct measurements of chlorine. Always care should be taken as calibration has to be done by a person who is having experience and knowledge of flow meter calibrations inorder not make mistake.

Maintenance Task: Clean the Flow SensorsTechnical Level, One of the key maintenance tasks is to clean flow sensors regularly. Further, debris and dirt can accumulate in flow sensors which causes the proper reading of the device to diminish over time. However, if the sensors are cleaned regularly then this can reduce deterioration of the meter over time and help to provide accurate results.

Another crucial thing to do, which needs doing on a regular basis is calibration. The frequency of whether you calibration should be done monthly, every few months or once a year will depend on the specific industry and application. It is important to follow the manufacturer's recommendations of how frequent calibration should take place and always ensure a qualified technician does this for you.

Our location is excellent. Within 60 kilometers, there Zhengzhou International Logistics Port, the largest air-based logistics port in Central China, with abundant options for logistics and air; there are a variety of international express companies such as FEDEX, UPS, DHL, TNT, etc. assigned to cooperate. At the same the same time, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China that has direct railway analog flow meter channels that connect that connect to Central Asia, Europe and Russia. Therefore, shipping from our country is swift and secure, and there are many routes pick from.

We have received various analog flow meter China. In addition, we received the certification for explosion proof which is accepted by the mining industry in China (Ex d ia (ia Ga) q T6 Gb) In addition, we are applying for the internationally recognized ATEX certification. Furthermore, our production workshop completed all of certifications and certificates for quality system and environmental system. It also has obtained CE certificates.

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is analog flow meter to ensure that every product is flawless when leaves the factory.

Since many years our company has collaborated with some of most prestigious universities in the nation to attract and train top technical talent, which guarantees that we're always expanding and adding new products. We have always found solutions to various issues and pain points faced by different customers in various projects. In the meantime, our talent strategy will also help develop professional technical talents, providing dedicated analog flow meter laboratories working with companies that are at the forefront of technology the field to study.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy