Koks yra skaitmeninio turbininio srauto matuoklio veikimo principas? Šios turbinės sukasi, kai per jas tekęs skysčio srautas naudojant detalį, vadinamą turbina. Turbina turi lopis (panašias į vėjožolės avarius), pritvirtintus prie ašies. Kai skysčio srautas teka per lopius, jie sukelia sukimosi judesį, kai išeina iš turbinės. Yra jutiklių, kurie skaičiuoja, kiek kartų sukasi turbina. Ši informacija nusiunčiama kompiuteriui, kuris kartu su matuoklio specifikacijomis apskaičiuoja, kaip buvo perkeltas skysčius.

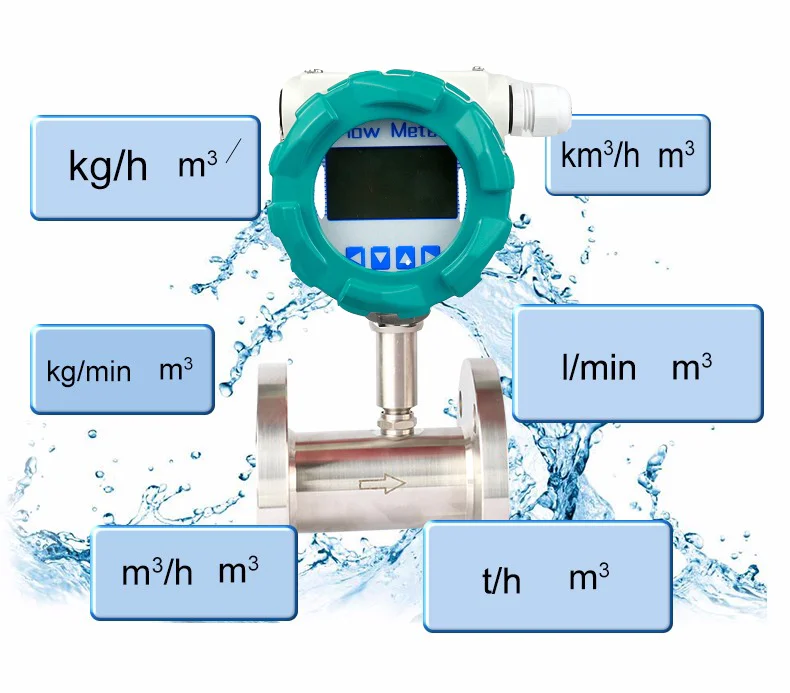

Pagrindiniame dydžiuje skaitmeninis turbininio tipo srauto matuoklis naudojamas skaičiuojant debesų kiekį, einantį per jį (per laiką), nors kitos priemonės gali pateikti duomenis, paratytus automatizacijai. Pavyzdžiui, jos gali matuoti skysčius litrais, galonais arba kubiniu metru. Toks tikslus matavimas yra labai svarbus, nes leidžia gamyklų darbuotojams naudoti mažiau skysčių ir taupyti pinigus. Tai leidžia jiems priimti geresnius sprendimus dėl to, kaip jie valdo savo mašinas ar vykdo procesus, žinant tikslų skysčio kiekį, kuris naudojamas.

Turint tai omenyje, yra daug puikių būdų, kaip naudinga naudoti skaitmeninius turbininius srauto matuoklius gamtose ir pramoniniuose veiksmuose. Jie siekia taupyti įmonėms pinigus, pirmiausia dirbant su atliekomis. Operatoriai gali užtikrinti, kad naudojami tik tie skysčio kieiniai, kuriuos jie tikrai reikalauja savo operacijoms, naudojant šiuos matuoklius. Toks tikslus matavimas užtvernuo jų naudoti daugiau skysčio nei reikia, o tai gali būti pinigų taupymas ilgą laiką.

Ne tik tai yra puikus pinigų taupymo strategijos būdas, digitaliniai turbininiai srauto matuokliai taip pat užkariauja darbuotoją daryti brangius klaidas. Tokie matuokliai sukurti aptikti bet kokią nesuderinamumų sraute. Atsirandant problemoms, jie gali skambėti už pagalbos, norint pranešti įsikišimo personalui. Idėja naudoti išmestinius failus egzistuoja dėl priežasties, ir ji labai svarbi, nes kitaip kasdienės operacijos nebūtų vykdomos kaip tikimasi. Matuokliai gali juos sustabdyti, kad jie nepradėtų augti į didesnius problemas, kurie galėtų trukdyti operacijoms.

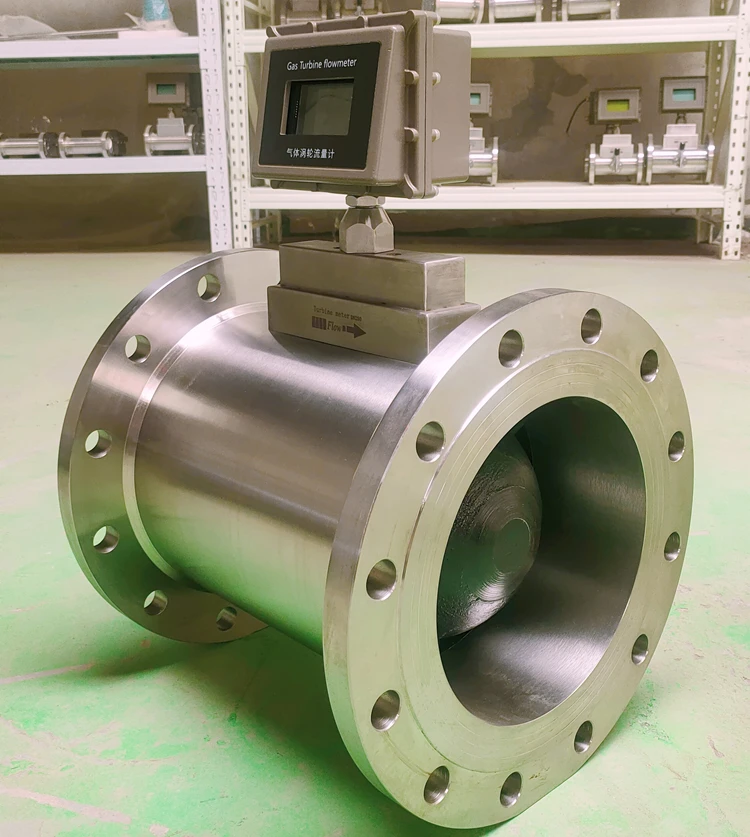

Keli svarbūs dalykai, kurie turi būti įvertinti renkant tinkamą skaitmeninį turbininį srautometrį. Operatoriai pirmiausia turi nustatyti, koks skysčio rūšis bus matuojamas ir kaip greitai jis tekės. Skirtingi skysčiai turi skiriasi charakteristikas, kurios gali paveikti srautometro veikimą, pvz., skysčio klampumą ir tankumą. Tai svarbu darbuotojams suprasti, kad jie galėtų pasirinkti toks matavimo prietaisą, kuris atitinka užduotį.

Galiausiai, reikia pažiūrėti į skaitmeninio turbininio srautometro kainą. Pagal mūsų stebėjimą, pigesni kainojantys modeliai yra susiję su paprastesniais matavimo kategorijomis. Tačiau prisiminkite, kad tiksliau nustatytas srautometras gali atsipirkti ilgalaikiu. Tai gali padėti jūsų kompanijai išsaugoti pinigus ilgą laiką, o jei atliksite daug matavimų kasdien (o tikriausiai jų yra pakankamai), investuoti į geresnį srautometrą padarys didelę skirtumą.

Pažangos turbininių srautometrų našumąTurbininiai srautometrai per metus labai tobulėjo, o daugybė patobulinimų jais padarė tiksliausius ir patikimesnius. Mikroprocesoriai - didžiausias pažanga Net mažesni kompiuterių modeliai gali apdoroti didžiulį duomenų kieštą labai trumpu laiku. Tai užtikrina, kad jie galėtų matuoti gėrimus papildomai tiksliau srautometrams. Naujesni LCD ekranai taip pat buvo sukurti, kad vartotojams būtų dar lengviau skaityti informaciją.

Esame palankioje geografinėje padėtyje. Mes esame aukštesnėje geografinėje zonoje. Jie patikimi bendradarbiavimu; tuo pačiu metu Zhengzhou miestas, esantis už 50 kilometrų nuo mūsų, yra didžiausias geležinkelio mazgas Kinijoje, tiesioginėmis geležinkelio transportavimo trasomis į Centrinę Aziją, Europą ir Rusiją. Siuntimas iš mūsų yra greitas ir saugus – yra daug skaitmeninių turbininių srauto matuoklių, iš kurių galima pasirinkti.

Mūsų įmonė jau keletą metų dirba su žinomais vietiniais universitetais, kurie geba atrinkti ir apmokyti geriausius techninius specialistus. Tai ne tik užtikrins mūsų nuolatinį technologinį tobulėjimą ir patobulinimus, bet taip pat leis nuolat tobulinti ir kurti naujus produktus. Mes galime rasti sprendimus įvairioms problemoms ir skausmingoms vietoms, su kuriomis susiduria klientai dirbdami su savo skaitmeniniais turbininiais srauto matuokliais. Tačiau talentų strategija taip pat padės ugdyti profesionalius techninius specialistus, teikiant specifines tyrimų laboratorijas ir bendradarbiaujant su pažangiomis technologijų įmonėmis verslo srityje.

Turime visapusišką aukštos kokybės matavimo ir kalibravimo įrangos asortimentą ir gavome sertifikavimą iš Kinijos metrologijos instituto, kad užtikrintume, jog kiekvienas srautmatis, išeinantis iš gamyklos, būtų sukalibruotas naudojant tikrąjį srautą ir būtų tikslus bei tikrai preciziškas. Taip pat turiu visiškai sandarų ir slėgio bandymo įrangą. Tai reiškia, kad įrenginys turi pakankamai jėgos ir gebėjimų gaminti aukšto slėgio prietaisus arba IP68 apsaugą. Turime griežtą ir visapusišką kokybės kontrolės skyrių, kurio kiekvienas inspektavimo etapas užtikrina, kad kiekvienas produktas išėjus iš skaitmeninio turbininio srautmatio būtų be defektų.

Mes pirmiausia gavome įvairių formų patvirtinimo sertifikatus Kinijoje, antra – sprogimui atsparumo sertifikatą skaitmeniniam turbininio srauto skaitikliui, kurį išdavė anglių kasybos pramonė (Ex d ia(ia Ga) q IIC T6 Gb), ir siekiame tarptautinio ATEX sprogimui atsparumo sertifikavimo; be to, mūsų gamybos cechas praėjo visą komplektinę aplinkos ir kokybės sistemos sertifikaciją ir gavo sertifikatus; galiausiai, taip pat turime CE sertifikatus, pilną ISO kokybės sertifikaciją ir pan.

Autorių teisės © Kaifeng Kamboda Pramonės prietaisų UAB. Visos teisės saugomos - Privatumo politika