Avez-vous déjà réfléchi à la manière dont une machine sait qu'il n'y a plus assez de liquide dans un réservoir ? Le jaugeage ultrasonore : C'est ici que les jauges ultrasonores entrent en jeu. Une jauge ultrasonore est un outil unique qui indique le niveau de liquide dans un réservoir sans contact ni détection directe. Idéal pour les réservoirs stockant différents liquides tels que l'eau, le lait et l'huile. La technologie est une chose incroyable !

Comment fonctionnent les capteurs de niveau ultrasoniques et où sont-ils utilisés ? Cela fonctionne ainsi : l'appareil envoie des ondes sonores qui se réfléchissent sur le liquide dans le réservoir. Il calcule ensuite combien de temps il faut aux ondes sonores pour revenir, ce qui est lu sur un compteur. Il mesure la position d'un objet flottant au-dessus grâce à une détection sonore ultrasonique ; nous calculons combien de temps cela prend pour que l'ultrason se réfléchisse afin de connaître la distance à laquelle se trouve notre liquide par rapport à l'appareil. Puisque la partie verrouillée n'a pas encore fourni de solution, cela indique combien de liquide se trouve dans ce réservoir. C'est de la magie, mais avec ce genre de puissance, c'est toujours le cas !

Lorsque les jauges ultrasonores n'avaient pas encore été inventées, il fallait toucher le liquide pour mesurer son niveau à l'intérieur. Comparativement, les anciennes méthodes de prise de mesures n'étaient pas très précises et pouvaient même être dangereuses lorsqu'on avait affaire à des liquides nocifs ou autrement dangereux. Imaginez si vous deviez mesurer quelque chose de dangereux ou corrosif !

Beaucoup mieux que ces vieilles méthodes, il y a les jauges ultrasonores ! Comme elles ne sont pas en contact avec le liquide, ces raffineries sont plus sûres et plus exactes. Incroyablement, ces appareils peuvent même mesurer à distance le niveau des liquides dans des réservoirs où vous ne pouvez pas regarder avec l'œil nu. Cela les rend parfaits pour être utilisés dans de nombreux métiers et industries où un haut degré de sécurité est essentiel.

Une grande partie des appareils de mesure nécessitent une configuration et une calibration approfondies pour bien fonctionner. C'est un processus de calibration. Pour moi, cela ressemble à l'accordage d'une corde de guitare jusqu'à ce que l'accord sonne parfaitement. La calibration peut être un processus long et difficile à suivre, surtout lorsque vous avez d'autres tâches en cours.

Calibration du Mètre de Niveau Ultrasonique ! La meilleure partie est que vous n'aurez pas besoin de faire beaucoup de calibration avec un mètre de niveau ultrasonique ! Les gimbals peuvent être configurés en quelques secondes, et vous n'aurez pas besoin de réajuster ensuite. Cela économise du temps et réduit les coûts pour toute entreprise, rendant les mètres de niveau ultrasoniques l'un des choix populaires de nombreuses organisations.

Ces capteurs sont utilisés pour détecter les niveaux de carburant dans les réservoirs et pipelines souterrains des industries pétrolières et gazières. Ils sont également chargés du contrôle des niveaux d'eaux usées, afin de s'assurer qu'ils ne nuiront pas ou n'auront aucun impact sur l'environnement. L'industrie agroalimentaire utilise des capteurs ultrasonores pour mesurer les volumes, comme le lait, le vin ou le jus de fruits, afin de garantir que les consommateurs reçoivent des produits aux bonnes propriétés.

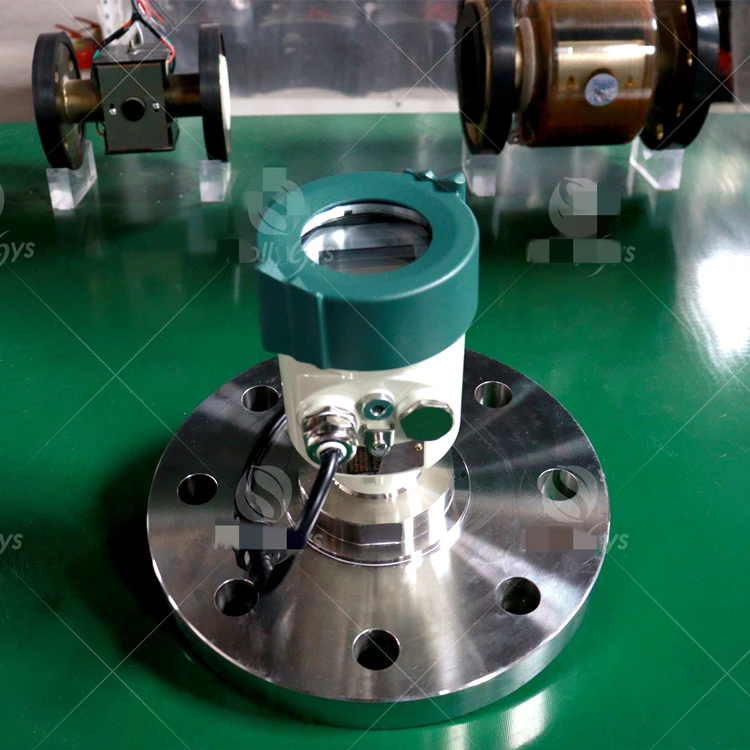

Nous disposons d'une gamme complète d'équipements de mesure et d'étalonnage de haute qualité et avons obtenu une certification délivrée par l'Institut chinois de métrologie, afin de garantir que chaque débitmètre expédié depuis notre usine a été étalonné avec un débit réel et offre une précision exacte et fiable. Nous possédons également des équipements complets d'étanchéité et de test de pression. Cela permet de s'assurer que nos installations ont la solidité et la capacité nécessaires pour fabriquer des instruments haute pression ou dotés d'une protection IP68. Nous avons un département de contrôle qualité rigoureux et complet, et chaque étape du processus d'inspection garantit que chaque produit est parfait avant de quitter l'atelier du compteur de niveau ultrasonique.

Depuis de nombreuses années, notre entreprise collabore avec certaines des universités les plus prestigieuses du pays afin d'attirer et de former les meilleurs talents techniques, ce qui garantit que nous élargissons constamment notre offre et ajoutons de nouveaux produits. Nous avons toujours trouvé des solutions aux divers problèmes et points sensibles rencontrés par différents clients dans le cadre de divers projets. Par ailleurs, notre stratégie en matière de talents contribuera également au développement de professionnels techniques, en mettant à disposition des laboratoires spécialisés dans les débitmètres ultrasoniques qui travaillent avec des entreprises à la pointe de la technologie dans ce domaine.

Nous avons tout d'abord obtenu divers types de certificats d'approbation en Chine. Deuxièmement, nous avons reçu un certificat anti-déflagration reconnu par l'industrie minière du charbon (Ex d ia(ia Ga) q IIC T6 Gb) et nous cherchons à obtenir le certificat international ATEX anti-déflagration. En outre, notre atelier de production a mis en place un ensemble complet de systèmes de qualité et environnementaux certifiés, et a obtenu plusieurs certifications ; enfin, nous disposons également des certifications CE, des certifications de qualité ISO pour les débitmètres à ultrasons, etc.

Nous sommes dans une position géographique privilégiée. Nous bénéficions d'une zone géographique supérieure. Des coopérations nous ont été confiées ; en même temps, la ville de Zhengzhou, située à 50 kilomètres de nous, est le plus grand hub ferroviaire de Chine, avec des liaisons ferroviaires directes vers l'Asie centrale, l'Europe et la Russie. L'expédition depuis notre site est rapide et sécurisée, et il existe un large choix de débitmètres à ultrasons disponibles.

Droits d'auteur © Kaifeng Kamboda Industrial Instrument Co., Ltd Tous droits réservés - Politique de confidentialité