Il y a très longtemps, dans une galaxie pas si lointaine, il existait certaines entreprises qui fabriquaient des appareils appelés capteurs de débit thermique ou de masse. Ils sont importants car ils mesurent le débit de gaz à travers des lignes dans les usines, les centrales électriques et d'autres lieux. Cet article nous aidera à comprendre comment ces capteurs de débit massique thermique sont fabriqués et pourquoi ils deviennent un tel soulagement pour les entreprises afin qu'elles puissent accomplir leur travail efficacement ainsi que de manière sûre.

Un fabricant de capteurs de débit massique thermique est une entreprise qui produit des machines pour mesurer la quantité de gaz passant à travers des tuyaux. Ces machines ont de nombreux usages. Le circuit de gaz doit être parfait pour respecter la discipline de travail par les entreprises. Les travailleurs doivent savoir que le bon volume de gaz passe pour que les produits puissent être fabriqués correctement et que les bâtiments soient chauffés comme il se doit. Trop ou trop peu de gaz peut causer des problèmes et même des dangers. C'est pourquoi des mesures appropriées sont si cruciales.

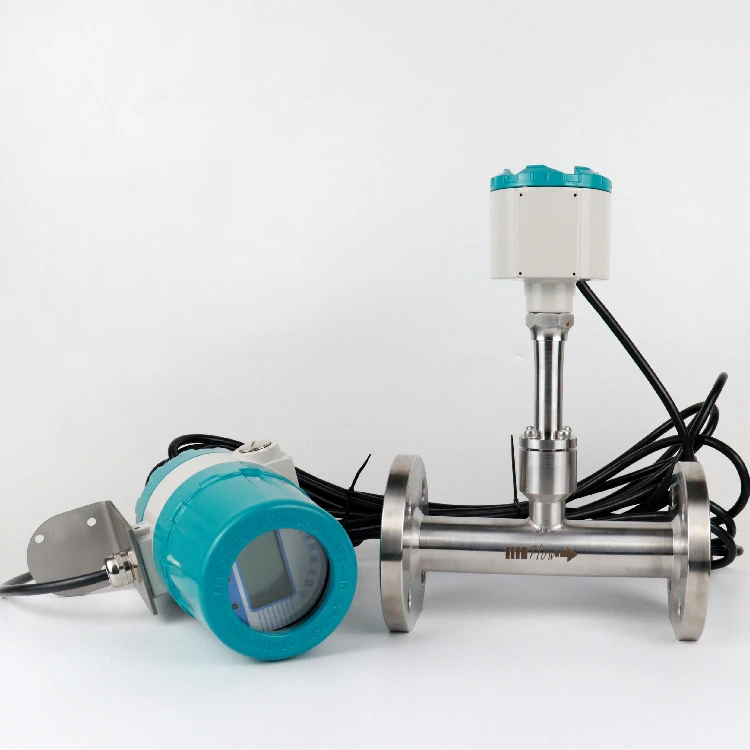

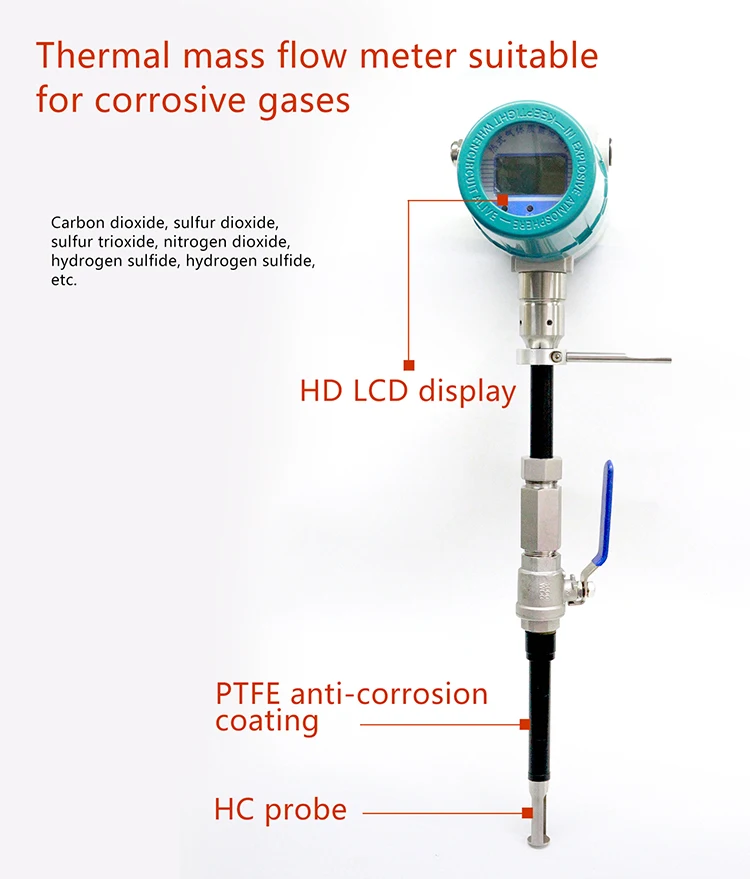

Les fabricants de compteurs de débit massique thermique sont des entreprises qui produisent ces appareils dans leur propre usine. Ils développent ces compteurs en utilisant des matériaux de première classe et des équipements sophistiqués. Un compteur de débit massique thermique est composé d'un capteur qui en est le cœur. Fabriqué en métal, ce capteur est optimisé pour détecter de petits changements de température. Le gaz entre dans le capteur et, en passant, refroidit son métal. Cet effet de refroidissement est mesuré par le compteur de débit massique thermique pour déterminer la quantité de gaz qui traverse le tuyau. Ces données sont ensuite utilisées pour prendre des lectures précises qui sont cruciales pour l'industrie.

Dans un fabricant de compteurs de débit massique thermique, de nombreuses personnes compétentes sont impliquées pour s'assurer que les machines sont correctement construites et fonctionnent bien. Et il y a des ingénieurs qui développent les machines, afin qu'elles puissent être utilisées en toute sécurité dans une usine et ailleurs. Les techniciens installent et assemblent les machines, effectuent des tests pour vérifier leurs capacités, ainsi que pour s'assurer qu'elles mesurent correctement le débit de gaz. Ce sont des normes très strictes en matière de fiabilité des machines. Il y a également des commerciaux qui appellent les clients et demandent quel type de compteur ils ont besoin pour leur cas. Ils peuvent vous aider à choisir le bon compteur pour vous et répondre à toutes vos questions connexes.

Les fabricants offrent les meilleurs outils de mesure du débit de gaz disponibles sur le marché pour d'autres industries grâce aux compteurs de débit massique thermiques. Ils s'assurent que leurs outils sont précis et parfaitement conformes, même dans les conditions les plus difficiles ou défavorables. Une large gamme de ces compteurs est produite par ces entreprises, qui ont compris que différentes industries ont des besoins variés, d'où la fabrication et la fourniture de tels types pour répondre aux diverses exigences. Par exemple, certains compteurs peuvent mesurer le débit de gaz dans de grandes conduites, tandis que d'autres seront plus efficaces pour de petites conduites. Les fabricants de compteurs de débit massique thermiques poussent toujours les limites en ce qui concerne les moyens de mesurer le débit de gaz et permettent ainsi aux entreprises d'avoir une meilleure visibilité sur leurs processus, améliorant ainsi leur efficacité.

Les compteurs de débit massique thermiques sont principalement utilisés par les fabricants dans le secteur industriel, car ils ont des applications dans diverses industries. Ils aident les usines à fabriquer des produits de manière sûre et efficace. Les compteurs de débit massique thermiques sont utilisés comme équipement d'inspection pour mesurer la quantité de gaz brûlée dans les centrales électriques pour produire de l'électricité. C'est un composant essentiel pour réguler la production d'énergie. HVAC : Les compteurs de débit massique thermiques gèrent également avec précision les systèmes de CVC (chauffage, ventilation et climatisation) pour chauffer ou refroidir les bâtiments. Ils assurent que le bâtiment reste confortable et sûr pour tous ceux qui s'y trouvent. Les opérations industrielles, telles que les usines, auraient beaucoup de mal à fonctionner sans compteurs de débit massique thermiques, ce qui entraînerait des problèmes importants.

Depuis de nombreuses années, notre entreprise collabore avec certaines des universités les plus prestigieuses du pays afin d’attirer et de former les meilleurs talents techniques, ce qui garantit une expansion continue et l’ajout régulier de nouveaux produits. Nous avons toujours su trouver des solutions aux divers problèmes et points sensibles rencontrés par nos clients dans différents projets. Parallèlement, notre stratégie en matière de talents contribue également au développement de professionnels spécialisés en technologie, en mettant à disposition des laboratoires dédiés de fabricant de débitmètres massiques thermiques, travaillant en étroite collaboration avec des entreprises à la pointe de la technologie dans ce domaine.

Nous avons tout d’abord obtenu divers certificats d’homologation de formes en Chine, puis nous avons obtenu un certificat antidéflagrant délivré par l’industrie minière charbonnière pour les débitmètres à masse thermique (Ex d ia(ia Ga) q IIC T6 Gb) et nous sommes actuellement en cours d’obtention de la certification antidéflagrante internationale ATEX ; par ailleurs, notre atelier de production a obtenu l’ensemble des certifications environnementales et qualité, et les certificats correspondants ont été délivrés ; enfin, nous disposons également de certifications CE ainsi que d’une certification qualité ISO complète, etc.

Nous disposons d’un ensemble complet d’équipements de mesure et d’étalonnage de précision, certifiés par l’Institut chinois de métrologie. Cela garantit que chaque débitmètre que nous expédions depuis l’usine est étalonné sur le débit réel, avec une précision élevée et rigoureuse. Je possède également tous les équipements nécessaires pour les essais d’étanchéité à l’eau et de résistance à la pression. Cela permet de s’assurer que l’usine que je dirige dispose de la capacité technique requise pour fabriquer des instruments haute pression, soit sur mesure, soit dotés d’une protection IP68. Nous disposons d’un service qualité strict et complet. Chaque étape du processus de fabrication des débitmètres massiques thermiques est conçue pour garantir que chaque article quitte l’usine dans un état parfait.

Nous sommes dans une position géographique privilégiée. Nous disposons d'une zone géographique supérieure. Ils sont chargés de la coopération ; en même temps, la ville de Zhengzhou, située à 50 kilomètres de nous, est le plus grand centre ferroviaire de Chine, avec des lignes de transport ferroviaire directes vers l'Asie centrale, l'Europe et la Russie. L'expédition depuis chez nous est rapide et sécurisée, il existe de nombreux fabricants de débitmètres massiques thermiques parmi lesquels choisir.

Droits d'auteur © Kaifeng Kamboda Industrial Instrument Co., Ltd Tous droits réservés - Politique de confidentialité