Did You Know That How Gas and Liquid Measured Every day in the Big Factories. This is the process known as flow measurement, which for one reason or another it matters. Flow measurement allows factories to understand their consumption of gas/liquid products and thus the quantity needed in order to produce them. In lieu of this information, the factories would have a very difficult time operating effectively.

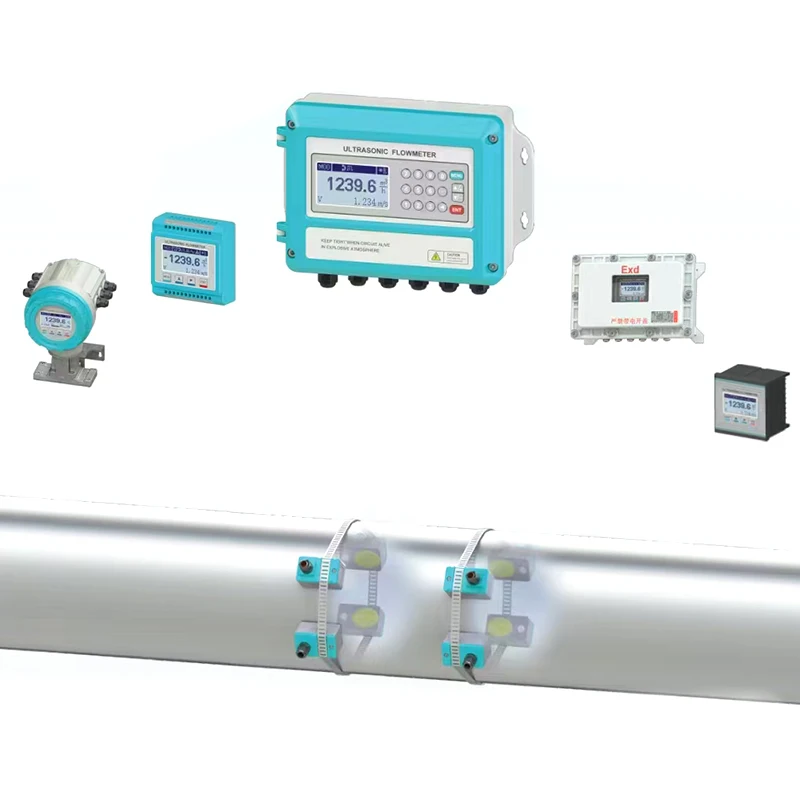

These meters are nice because they do not come in contact with the gas or liquid which is being measured, also the KAMBODA's product such as ultrasonic water flow meter. They used sound waves instead of having to physically touch the substance itself, and measured how long it would take for a blast of this signification bounced off back. The rate at which the sound waves return gives information to the ultrasonic meter about how speedily is substance flowing. This is a method for measuring with high accuracy without disruption the flow.

The many advantages of ultrasonic flow meters make them an excellent selection for industries. The first and perhaps most important of which is that they are non-invasive. This means flow sensors are all non-invasive whilst other flow meters (mechanical or magnetic) have to touch the measuring substance itself. Because ultrasonic meters do not come into contact with any foreign body, they are unlikely to be damaged or clogged.

Another predominantly good point is that ultrasonic meters also have the ability to measure both Gasses and Liquids, same with the air gauge pressure supplied by KAMBODA. While for some other flow meters, it is only able to measure gas or liquid. This, therefore, serves as an advantage to boost the usability of ultrasonic counters for all sectors and enables just one kind of meter being put to use within a variety connected with activities.

These two types of sound waves are a "primary" wave and a "sensitive phase, similar to the KAMBODA's product like vacuum pressure transmitter. The transmitting wave is sent through the medium, and on the opposite side. it has to be read back by a receiving wave. The ultrasonic meter measures how long it takes for the two waves to collide and uses that time in combination with mechanics based on fluid dynamics of stateside astrophysics. This is akin to a game of catch but involves sound waves.

Ultrasonic meters are particularly beneficial for their high accuracy, same with the flow water sensor built by KAMBODA. Since they do not touch the substance being measured, there is little danger that the meter will be blocked by debris in a pipeline. Which implies that ultrasonic water meters have the ability to measure accurately for a protracted duration. It is especially crucial for gas or liquid industries, since there will be a huge amount of money wasted in case with an error measurement even they are little ones.

Not only the ultrasonic meters are accurate but they can also save time of various industries, identical to KAMBODA's product diesel flow meter. Installation and maintenance processes are also simplified. Sensor Heads are mounted away from the process itself so they can be left undisturbed for extended periods without requiring any shutting down to perform maintenance or cleaning. The industry now has less downtime, which can save them a lot of money in the long term.

We have full-set precision calibration measurement equipment. In addition, we have obtained certification from China Institute of Metrology. This ensures that each flow meter we send from the factory is calibrated to actual flow that is precise and with a high degree of precision. I also have complete pressure and tension testing equipment and waterproof testing equipment to ensure our factory is able to withstand the rigors of and capability to design IP68 or high-pressure protection instruments. We have a strict and complete quality control Ultrasonic meter. Every step of inspection process is to ensure that every product is flawless before it leaves the factory.

We have received various certifications China. Second, we received the explosion proof certificate which is accepted by the mining industry in China (Ex d ia (ia Ga) q T6 Gb), we are also trying to obtain the internationally recognized ATEX certificate. In addition, our production workshop completed all of certifications as well as certificates for Ultrasonic meter systems, environmental system, and have obtained CE certificates.

We are situated in a premium geographical location. Within 60 kilometers, there is Zhengzhou International Logistics Port, the largest port air logistics in Central China, with abundant logistic and air options; there are a variety of international express companies, such as FEDEX, UPS, DHL, TNT, etc. Zhengzhou City is 50 km away and is also the Ultrasonic meter rail hub in China. It is connected railway transportation routes Central Asia, Europe, and Russia. Shipping with us is secure and quick, with a variety of options to choose from.

Our company has been cooperating renowned universities in the country for several years, has been able to recruit and training top technical talent. This will not only guarantee our ongoing technological advancement, but also continuously improves and introduces new products. We can find solutions to various problems and issues that our customers encounter in their various projects. The talent plan we have developed also helps to develop professionals with Ultrasonic meter skills by providing specific research labs for and collaborating within the industry with top technology company's study.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy