Ultrasonic level meters are rad pieces of tech that do the job of calculating exactly how much liquid is inside of a tank or silo. Factories and plants use them all the time, to keep everything running well. But how do they work? Let’s find out!

Ultrasonic level meters measure the level of liquid in a tank using sound waves. The meter sends out a sound wave that reflects from the liquid surface and then returns to the meter. By determining how long it takes for the sound wave to come back, the meter can tell how far the liquid is. Isn’t that neat?

There are so many good reasons to install ultrasonic level meters in factories. For one, they are highly precise, so you can rely upon the measurements. They don’t come in contact with liquid, so you can leave them in without concern they’ll get dirty or ruined. And they are just straightforwardly simple to install and use, perfect for high-traffic areas.

Here are some things to consider when choosing the best ultrasonic level meter. The first thing to think about is the size of the tank that you want to measure. Some meters are better suited to smaller tanks, others for larger tanks. You also have to consider the type of liquid you will be measuring, some meters are made for specific liquids. And of course, don't forget the budget – there are lots to choose from, so pick a unit that fits your needs and your bank account.

Just as is the case with any other device, ultrasonic level meters must be verified and maintained to ensure that you get the proper readings. Calibration is the process of comparing your meter’s measurements to known standards and adjusting if necessary. This will keep the meter in good working condition and provide you with accurate information. Regular maintenance is also key — keeping the meter clean and free from obstructions can make it last longer and work better, according to Licence.

Occasionally ultrasonic level meters can be difficult to use. One typical problem is the presence of bubbles of air in the liquid, which can disrupt sound waves and lead to incorrect readings. When you see this, attempt to squash out the bubbles or consider getting a different brand of meter: Electrical interference can be another issue which may cause the meter to act up or not work properly. To prevent this from happening, check that the meter is properly grounded and shielded from the surrounding electrical devices.

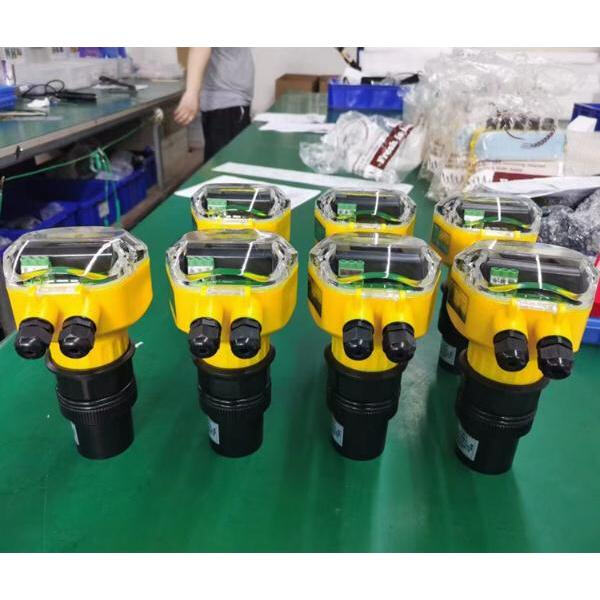

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is ultrasonic level meter to ensure that every product is flawless when leaves the factory.

Since many years our company has collaborated with some of most prestigious universities in the nation to attract and train top technical talent, which guarantees that we're always expanding and adding new products. We have always found solutions to various issues and pain points faced by different customers in various projects. In the meantime, our talent strategy will also help develop professional technical talents, providing dedicated ultrasonic level meter laboratories working with companies that are at the forefront of technology the field to study.

We are situated in a premium geographical location. Within 60 kilometers, there Zhengzhou International Logistics Port, the largest air-based logistics port in Central China, with abundant logistic and air options; there are many international ultrasonic level meter companies such as FEDEX, UPS, DHL, TNT, etc. Zhengzhou City is 50 km away, is biggest railway hub in China. It has direct railroad transportation routes that connect that connect to Central Asia, Europe, and Russia. Thus, shipping from us is fast and secure and there are plenty of routes to pick from.

We have received various certifications China. Second, we have obtained the certificate of explosion proof recognized by the coal mining industry in China (Ex d IA (ia Ga) q T6 Gb) We are also trying to obtain the international ATEX certificate. Furthermore, our manufacturing ultrasonic level meter has passed the necessary certifications and certificates our quality system, environmental system, and have obtained CE certifications.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy