Wondering how factories measure the speed of sustained or flowing liquids like water, oil etc? They have a specific tool known as Flow Meter Sensor! With the help of this tool, they get to know about flow rate which refers how fast a liquid is flowing. Flow meter sensors come in a variety of kinds, and one particular kind which appears to be the best is known as an ultrasonic flow meter sensor. The sensor even listens to the sound while water flows through it, cool!

Ultrasonic flow meters determine the speed of a liquid by sending up sound waves. You shoot sound waves from one end of a pipe to the opposite side. The sensor records the time it takes for these sound waves to travel from one side of gap wall sidewall. If it knows the distance sound must travel and how long that takes, then sensor can measure how fast liquid is moving in a pipe. This is a very smart way and it helps factories take correct measurements.

Ultrasonic flow meter sensors are quite popular nowadays and used in numerous industries for different use-case. In the chemical industry, they might measure how much liquid is being used to creating chemicals of different types. That matters greatly so that the proper dosages are used to safely build their products. The oil and natural gas enterprise additionally uses them to gauge the price of flowing crude via pipes in order that it could be transported effectively. This keeps leaks at bay and ensures that everything is done proficiently. The food and beverage industry can see how much liquid is put in the drink or sauce. Insuring The Right Amounts for recipes to Keep It Consistent and Tasty

Flow (decay): Ultrasonic flow meter sensors are non-invasive, that is they will have no impact on the way how a liquid flows. This is important, because the regular movement of liquid can result in wrong measurements due to disruption. Ultrasonic flow meter sensors guarantee that businesses are receiving proper measurements without interfering with their pipeline processes at all. Which in turn, results into more accurate output and smoother business operations.

While maintaining and keeping operational are very high on other flow meter sensor types. Basically, these are something that has to be cleaned and re-checked frequently as we must ensure they will provide us with the right readings. For businesses this also could be a time consuming and costly process. Those sensors need to be maintained, though — and that maintenance can disrupt the organization's operations since at least one person has to take time out of their schedules to ensure they are functioning correctly.

While with ultrasonic flow meter sensors, this extra care is not even required This is by far the most user-friendly brand, they are very accurate and designed to go on for a good while before crapping out. For the businesses, that translates into less money spent on maintenance and time wasted because they do not have to worry about when they will need to replace their flow meters. This enables them to devote more time on their work, rather than performing maintenance tasks.

For instance, if a business realises they are using far too much water in creating their products; such an aspect awakens them to the need of cutting back on this resource. According to her, this allows owners to save money and the environment as water is saved. Ultrasonic flow meter sensors ensure businesses are using the correct amount of liquid for their processes. So in a win-win, they are enabled to be more productive and efficient overall.

We have first obtained various types of approval certificates China Second we have received an explosion-proof certificate that is recognized by the coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb) and are trying to obtain the international ATEX explosion-proof certificate. In addition, our production workshop has completed an entire set quality system and environmental system certifications, and received certifications; lastly also have CE certifications; ultrasonic flow meter sensor ISO quality certifications, etc.

We have a great geographical location. We are located a more favorable geographical position. They are entrusted with cooperation; at the same simultaneously, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China with direct railway transport channels that connect that connect to Central Asia, Europe and Russia. Thus, shipping our country is swift and safe There are a variety ultrasonic flow meter sensor to pick from.

Over the years, our company worked with well-known ultrasonic flow meter sensor in the United States in order to train and recruit best technical talent. This assures us that we are constantly improving and adding new products. We have the ability to provide solutions for different problems and issues that our clients confront various projects. The talent plan we have developed also helps to develop professional technical talents by providing dedicated research labs and cooperating in the industry with advanced technology firms to gain knowledge.

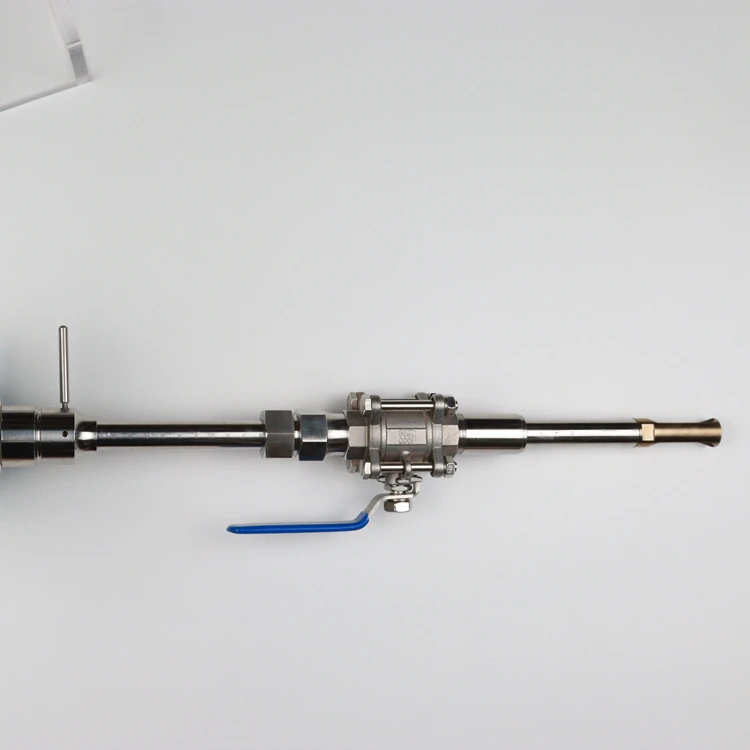

We have full-set, precise calibration and measurement equipment. We also certified by China Institute of Metrology. This means every flow meter we send from the factory is calibrated according to the actual flow that is precise and with a high degree of precision. I also have complete waterproof and pressure testing equipment. This will make sure that the factory I run is strong ultrasonic flow meter sensor and able to custom-make high-pressure instruments IP68-protection. Our quality control department is completely and rigorous. Every step is designed to ensure that the product is flawless once it has left the factory.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy