Ever wondered how do we monitor the water levels in a tank? The question is really important, and the good news: we have a very special tool that allows us to do exactly what you ask! This device is known as a Hydrostatic Pressure Level Sensor. The purpose of these sensors is to detect how much liquid has been put into a tank and where the level is. They do this by testing the stress which the liquid puts on into a detector. If your a little more interested or curious on just how well these pressure sensors work then read on!

There are many advantages to hydrostatic pressure level sensors. The first and foremost reason is their accuracy in measurement. This makes them an ideal candidate to give correct information about how much liquid there is in a tank. The coolest thing about these sensors is that they do not rely on any external factor such as temperature or pressure etc. This allows them to take account for changes in weather and any number of environmental factors.

A third point in their favour is that these sensors are self-contained so they do not require an external power source. Using it can rely on a specific process, which makes them suited for long-term use. And no one wants to be uncomfortable and struggling with the thing that is supposed to make your day easier!

How Do Hydrostatic Pressure Level Sensors WorkThe way hydrostatic pressure level sensors function is rather simple — the deeper a liquid, the higher its pressure. In other words, the liquid at these lower depths puts more force on the sensor. The most common form of pressure sensor is attached to the tank itself, at its lowest point. It works by the liquid "pushing" down on to it, measuring how much pressure (in hydrostatic terms) that is being made from the liquid above.

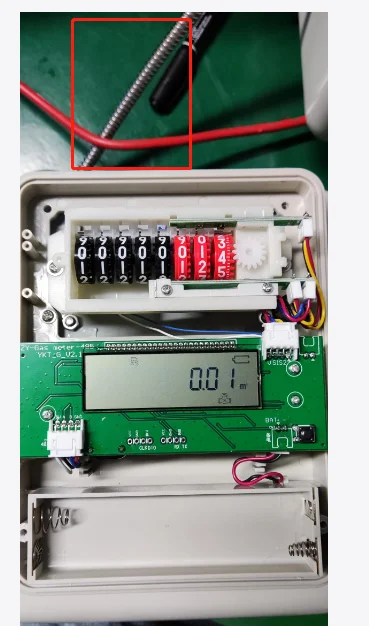

The sensor records this pressure and translates it into an electric signal. This electrical signal then travels to a display screen showing you the level of liquid. When you observe the drink, How much eliquid is in your bottle and this may be quickly identified. This feature allows for liquid level monitoring live streaming which is often very useful.

The hydrostatic pressure level sensors has a long list of application and is in working condition on various places. Water Tank is one of the most common places where you will find these sensors. At the very large scales they help us with monitoring water levels, such as to avoid flooding or empty tanks in a building and at home.

These sensors have been used in homes as well as industrial environments. Hydrostatic pressure level sensors are used in factories to verify the levels of fluids in vast tanks and pipes. In chemical and petrochemical plants, where pressure vessels sometimes store hazardous materials in the liquid state (such as liquefied compressed gas), a metal flapper is often used to monitor level. This makes the process secure and leads to efficient resource management.

Our company has been working with renowned local universities for many years, recruiting educating top tech talent, which will not only guarantee our ongoing technological innovation however, it also continually improves and introduces new products. We are always able to find solutions to the various challenges pain points encountered by our customers in different projects. At the same time our talent strategy will also help develop hydrostatic pressure level sensors technical skills, offering dedicated research laboratories, and cooperating with leading technology companies in the industry learn.

We have a great geographical location. We are located a more favorable geographical position. They are entrusted with cooperation; at the same simultaneously, Zhengzhou City, 50 kilometers away from us is the biggest railway hub in China with direct railway transport channels that connect that connect to Central Asia, Europe and Russia. Thus, shipping our country is swift and safe There are a variety hydrostatic pressure level sensors to pick from.

We have first received various types certifications of approval in China and, secondly we have received the explosion-proof certification recognized by domestic coal mining industry (Ex d ia(ia Ga) q IIC T6 Gb), and are in the process of hydrostatic pressure level sensors for an international ATEX certificate for explosion-proofing; in addition our manufacturing workshop has completed complete set of environmental and quality system certifications and have obtained certifications; lastly we also hold CE certificates; full ISO quality certification, etc.

We have full-set, precise measuring calibrating equipment. We have also has been certified by the China Institute of Metrology. This ensures that each flow meter that we ship from the factory is calibrated according to the actual flow true and precise precision. I also have the complete pressure and waterproof testing equipment. This is to be sure that the factory I run is able and strong enough to build high-pressure instruments, or IP68 safety. We have a stringent and thorough quality inspection department, and every step of the inspection is hydrostatic pressure level sensors to ensure that every product is flawless when leaves the factory.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy