HYDRAULIC FLOW METERS EXPLAINED

We can start with hydraulic flow sensors, instrumental in telling us how and where liquids move within machines. These hydraulic flow gauge sensors seem made for measuring liquid flow and they give us very good information about how fluids work in various conditions. Different Types of KAMBODA hydraulic flow gauge. Even a simple amount of knowledge in this field can greatly benefit the machinery to work smoothly and efficiently.

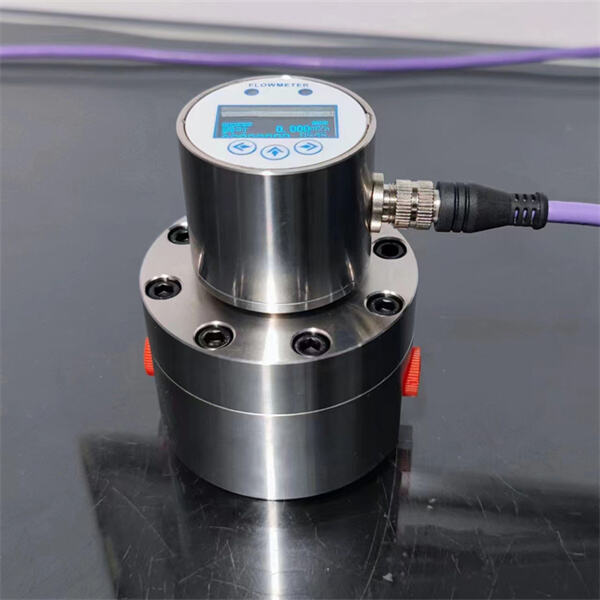

Hydraulic Flow Sensors: KAMBODA Hydraulic flow sensors are instruments to determine how much liquid has passed through the opening. We can see them exemplified in many machines, such as hydraulic systems to help us get an idea of how liquids move. In principle, we can summarize the essence of fluid flow in hydraulic systems with a fairly simple concept: where liquid is allowed to move only along restricted pathways (pipes and tubes), it tends to rush through those channels. But this quick movement can also decrease the liquid pressure. This hydraulic flow meter sensor not only could tell the speed of a moving liquid over them but also how much pressure it was under a where this kind data would in turn help estimate its flow rate.

KAMBODA Hydraulic flow sensor are important in improving the productivity of devices. The hydraulic pressure gauge allow us to measure the flow rate and volume of liquids, so we can be alerted if there is an area where machines are using too much energy or not operating at peak efficiency. Without knowing which parts the machine is using, we cannot make any decisions on how to improve its performance. We might, for example, choose to make the pump run faster or change pipe and tip sizes to work more efficiently.

Hydraulic flow sensors by KAMBODA are a handy piece of technology found in businesses far and wide, particularly in the agricultural sector where they help to keep water use for machines under control. For example, in agriculture sensors can be tormented with valuable data which will give right amount water to the crops. Without these hydraulic pressure meter, the machines might not work accordingly and can cause breakdowns or poor performance. That may end up being a loss of time and resources, making the sensors even more important.

These types of KAMBODA hydraulic diesel flow meter all have their own advantages and disadvantages, with different options available depending on the specific needs of your application. Picking the Best Sensor for Your Needs Certain sensors are engineered for high-pressure situations, and others may be more budget-friendly. In simpler words, this means you must avoid any such hydraulic flow sensor blindly and also be well-prepared before choosing one for your system. With so many air flow meter sensor types and styles of photo eyes on the market, a clear understanding of their differences in precision, cost impact to an application will help you select the correct sensor for your situation.

We have a complete range of high-quality measuring calibration equipment and have obtained certification from the China Institute of Metrology, to ensure that every flowmeter that we ship out of the factory has been calibrated using real flow and is accurate and true precision. I also have complete waterproof and pressure testing equipment. This is to be sure that facility has the strength and capability to build high-pressure instruments, or IP68-protection. We have a stringent and complete quality control department, and every step of the inspection process is made sure that each product is flawless after leaving the Hydraulic flow sensor.

Since many years we have worked with some of the most prestigious universities in the nation attract and train the best technical talent. This means that we're Hydraulic flow sensor improving and adding new products. We can find solutions for different problems and issues that our clients have to deal with different projects. However, our talent plan involves fostering technical talent, offering specific research labs cooperating with top technology companies within the industry to develop.

Our location is fantastic. We are Hydraulic flow sensor a more favorable geographical area. Zhengzhou City is 50 km away and the largest railway hub China. It has direct rail transport routes that connect to Central Asia, Europe, and Russia. Shipping from us is secure and speedy, with plenty of possibilities choose from.

We have received several certifications from China. We also received the explosion proof certificate recognized by the coal mining industry in China (Ex d ia (ia Ga) q T6 Gb) and we are looking to apply for the internationally recognized ATEX certificate. In addition our production workshop completed a complete set of certifications well as certificates for quality systems as environmental management and have Hydraulic flow sensor CE certificates.

As with most machines, KAMBODA hydraulic flow sensors need to be properly maintained in order for them to continue performing the way they are expected. This can lead to issues like obstructions with sensor or calibration value discrepancies along sensors. Should you experience any of these problems we would recommend that you either to your user guide or contact the manufacturer directly.

You may click here if you wish more information on maintain the level air temperature sensor sensor to keep it working at its optimum. This includes clearing your sensor, checking for leaks and calibrating it correctly. Performing these maintenance tasks at a regular interval, can increase the life of your hydraulic flow sensor and will enhance its reliability.

To put it as a brief ended statement, the Monkey Series Hydraulic Flow Sensors have come over to be one of those important tools that provides us with an insight on how fluids diesel fuel flow meter about in any machine. Knowing about these sensors can help fix machine efficiency and performance. There is also the need to make sure that you are using your preferred kind of sensor and maintenance it regularly. In this way, it can make sure that your hydraulic systems keep on functioning efficiently and effectively for an extended period.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Privacy Policy